-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Protection for the Pince Lucas of Darkness

- Thread starter LuckyLuke

- Start date

Keoke

Great Pumpkin

Offline

Highly debatable. However, IMOP NONE--Fwiw--KeokeLuckyLuke said:What grease should be used when mounting the cable connectors of a Lucas wiring harness?

My idea was to use some grease to prevent moisture from getting into the connectors!

P.S. Did you find any grease or moisture in em when you took them apart??

Offline

My 50 year old wiring harness was pretty beat up but had no bullet connector contact problems. When I installed the new wiring harness no grease in the connectors.

A lot of late model cars seem to fill every connection with dilectric grease. Not really sure if it helps keep out moisture or just retain any moisture that does get in. It certainly is messy & collects a lot of dirt.

D

A lot of late model cars seem to fill every connection with dilectric grease. Not really sure if it helps keep out moisture or just retain any moisture that does get in. It certainly is messy & collects a lot of dirt.

D

R

RonMacPherson

Guest

Guest

Offline

Dielectric grease helps maintain contact and protect against water intrusion. Why wasn't it used 50 years ago?

It wasn't around then. You will find most of the upscale Marques are starting to include it at locations they consider consequential.

It wasn't around then. You will find most of the upscale Marques are starting to include it at locations they consider consequential.

John Loftus

Darth Vader

Offline

Dave Russell said:A lot of late model cars seem to fill every connection with dilectric grease.

This is what prompted me to use it inside my new harness connections (and spark plug wire boots).

I would be very surprised that they would go through the expense and hassle of doing this if it did not have proven benefits in terms of corrosion resistance, reliability and reduced warranty service. As for the dust/dirt, I use the small applicator tip to apply the grease inside the connector and after everything is firmly pushed together clean up any excess (if any) that makes it to the outside.

Cheers,

John

Keoke

Great Pumpkin

Offline

RonMacPherson said:Dielectric grease helps maintain contact and protect against water intrusion. Why wasn't it used 50 years ago?

It wasn't around then. You will find most of the upscale Marques are starting to include it at locations they consider consequential.

Yep they put that junk in there to save the cost of tining or plating the connector pins. By upscale do you mean "Ford"---Keoke

OH! by the way it was around 50 years ago but every one realised it be for Axles.--- /bcforum/images/%%GRAEMLIN_URL%%/grin.gif

OH! #2 A dielectric is an " insulator " and does not help maintain contact.

eschneider

Jedi Warrior

Offline

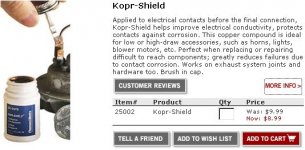

With respect to everyone's personal opinion and experience, another alternative is "Kopr-shield".

Its a conductive contact grease sold by Eastwood. Since it's conductive, you don't want to use it anyplace where two connectors might short out (i.e., when rebuilding a switch)

I recently had a TR6 customer who was having all sorts of electrical demons with a brand new wiring harness. After tracing 3 problems to connectors, we pulled all the connectors and greased 'em. No complaints since.

We are located in a humid, dirty urban environment though - bad for electrical connections.

Where kopr-shield is't practical, I use silicone grease in moderation. Seems to keep surface corrosion at bay, and keeps bullet connectors from getting "stuck".

Just confusing the answer with another alternative. 8)

Glad to be of service!!!!!

Its a conductive contact grease sold by Eastwood. Since it's conductive, you don't want to use it anyplace where two connectors might short out (i.e., when rebuilding a switch)

I recently had a TR6 customer who was having all sorts of electrical demons with a brand new wiring harness. After tracing 3 problems to connectors, we pulled all the connectors and greased 'em. No complaints since.

We are located in a humid, dirty urban environment though - bad for electrical connections.

Where kopr-shield is't practical, I use silicone grease in moderation. Seems to keep surface corrosion at bay, and keeps bullet connectors from getting "stuck".

Just confusing the answer with another alternative. 8)

Glad to be of service!!!!!

Keoke

Great Pumpkin

Offline

Well Eschneider, you just rang my bell again. When in this world did you ever see a grease that was conductive, ain't no such animal around. What is being done is the marketing people need some type of a gimmick to sell their product. So the take a dielectric; "Grease", fill it with copper granules and lacking any real imagination call it conductive grease.Grease is not conductive and the copper granules are the components that perform the conductive function the grease just keeps them put. OTOH ,Silicone grease used as you stated IMOP is a better choice.----Keoke

John Loftus

Darth Vader

Offline

Keoke said:..Silicone grease used as you stated IMOP is a better choice.----Keoke

Silicone grease/paste and dielectric grease are apparently the same thing(or mighty close)

dielectric silicone grease

AndrewMawson

Jedi Trainee

Offline

There is a product here in the UK called Electrolube, that removes oxide films on contacts:

https://www.electrolube.com/docs/contactlube.html

I first found it in use cleaning switch contacts in dirty process control environments, but now keep a spray can in the workshop for all sorts of odd contact / corrosion problems. Last usage was yesterday on the battery contacts of a radio transmitter used to track the path of underground drains by being pushed down them - hence the corrosion issues!

It's marvellous stuff, and although not originally put on bullet connectors, I have used it when re-assembling my wiring harness.

AWEM

https://www.electrolube.com/docs/contactlube.html

I first found it in use cleaning switch contacts in dirty process control environments, but now keep a spray can in the workshop for all sorts of odd contact / corrosion problems. Last usage was yesterday on the battery contacts of a radio transmitter used to track the path of underground drains by being pushed down them - hence the corrosion issues!

It's marvellous stuff, and although not originally put on bullet connectors, I have used it when re-assembling my wiring harness.

AWEM

tahoe healey

Yoda

Offline

Didn't point sets use to COME with a small bit of dilectric grease for the dizzy cam?

Keoke

Great Pumpkin

Offline

tahoe healey said:Didn't point sets use to COME with a small bit of dilectric grease for the dizzy cam?

--Points! whats that TH ?? /bcforum/images/%%GRAEMLIN_URL%%/grin.gif I think some companies eons ago included plain ole grease for the cam with their points. However, I have Lucas NOS Dizzy point sets here an there ain't no grease in them.----Keoke-- /bcforum/images/%%GRAEMLIN_URL%%/nonod.gif

And that stuff that Greg W used ain't nothin but tooth paste with some different writin on the outside.-- /bcforum/images/%%GRAEMLIN_URL%%/laugh.gif

John Loftus

Darth Vader

Offline

Hi T.H.,

The point cam lube I have is different than the dielectric/silicone grease. It it formulated to keep the rubbing block from wearing (as fast) which changes the point gap.

Cheers,

John

The point cam lube I have is different than the dielectric/silicone grease. It it formulated to keep the rubbing block from wearing (as fast) which changes the point gap.

Cheers,

John

John Loftus

Darth Vader

Offline

Keoke said:tahoe healey said:And that stuff that Greg W used ain't nothin but tooth paste with some different writin on the outside.-- /bcforum/images/%%GRAEMLIN_URL%%/laugh.gif

no wonder he has such pearly white teeth! /bcforum/images/%%GRAEMLIN_URL%%/grin.gif

Keoke

Great Pumpkin

Offline

John Loftus said:Hi T.H.,

The point cam lube I have is different than the dielectric/silicone grease. It it formulated to keep the rubbing block from wearing (as fast) which changes the point gap.

Cheers,

John

Yeah I bet it been formulated alright, prolly just plain ole white vaseline fomulated in a new package.---Keoke-- /bcforum/images/%%GRAEMLIN_URL%%/lol.gif

Johnny

Darth Vader

Offline

GregW said:I picked this stuff up at a local hardware store. I still had some of the ¼ oz tube left after installing the harness.

Yeah and Marth Stewart says to use vegetable oil on the light bulbs to make them easier to come out. She must have learned that little trick in prison.

GregW

Yoda

Online

Yeah, the plaque just sssslllliiiiddddeeeessss right off. /bcforum/images/%%GRAEMLIN_URL%%/grin.gifKeoke said:And that stuff that Greg W used ain't nothin but tooth paste with some different writin on the outside.-- /bcforum/images/%%GRAEMLIN_URL%%/laugh.gif

eschneider

Jedi Warrior

Offline

Ding-ding!!!

you make it so easy to torment you. <laugh>

here is the stuff. And it appears you are, indeed correct (not surprising) - reading the description closely, it says "promotes conductivity"..... rather than being conductive.

Keoke said:Well Eschneider, you just rang my bell again. When in this world did you ever see a grease that was conductive, ain't no such animal around. What is being done is the marketing people need some type of a gimmick to sell their product. So the take a dielectric; "Grease", fill it with copper granules and lacking any real imagination call it conductive grease.Grease is not conductive and the copper granules are the components that perform the conductive function the grease just keeps them put. OTOH ,Silicone grease used as you stated IMOP is a better choice.----Keoke

you make it so easy to torment you. <laugh>

here is the stuff. And it appears you are, indeed correct (not surprising) - reading the description closely, it says "promotes conductivity"..... rather than being conductive.