YakkoWarner

Jedi Warrior

Offline

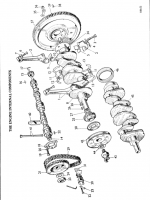

I had to replace the starter on my car which has not run in many years - while I have the engine out I tested the starter with a fresh newly charged battery and while the solenoid moved the gear to the engaged position with much authority, the motor itself turned lethargically slow even while on the bench with no load. So I ordered a new starter, not completely unexpected. My question is on the flywheel - the ring gear has some slight wear but it doesn't look terrible. The clutch mating surface has some corrosion - it may clean up OK or there may be some pitting; I have not gotten to that yet. Since I'm replacing the starter I am considering simply replacing the flywheel, that way I get a fresh ring gear and a known good clutch mating surface and less chance of prematurely wearing out the brand new clutch pack I am going to install.

It LOOKS for all the world like you remove a handful of bolts and take the flywheel off. My suspicion is that this is deceptive. Do you have to open up the pan and start taking bearings apart to access the other side of those deceptive looking bolts? Does it have to be mirror-finish smooth? How will installing a new flywheel impact engine balance? Is this something I need to have an actual engine builder undertake to get right? Do I need to involve members of the clergy and hold rituals for successful outcome? I've never pulled one of these off before, I don't want to ruin the engine by getting it wrong.

It LOOKS for all the world like you remove a handful of bolts and take the flywheel off. My suspicion is that this is deceptive. Do you have to open up the pan and start taking bearings apart to access the other side of those deceptive looking bolts? Does it have to be mirror-finish smooth? How will installing a new flywheel impact engine balance? Is this something I need to have an actual engine builder undertake to get right? Do I need to involve members of the clergy and hold rituals for successful outcome? I've never pulled one of these off before, I don't want to ruin the engine by getting it wrong.

Hey Guest!

Hey Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>