-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PCV VALVE [or not!] 67 BJ8

- Thread starter ttrotter

- Start date

Offline

Getting back to the question posted by the original poster, I'm unclear how a PCV valve can help reduce oil loss from the areas he mentions. I would have thought that the installation of any valve will restrict rather than increase the venting of the system. I believe that the purpose of the valve is to limit the amount of gasses and vapours returned to the intake during certain phases of the engine operations when it is deemed to be detrimental to performance efficiency. ...

The original poster is annoyed by leakage from the rear seal and timing chain cover, which my be the front seal. By creating a vacuum in the crankcase, air will tend to be drawn into the crankcase past these seals or any other small path open to it. Thus, oil will tend to be pulled into the engine at these leakage paths. So would dirt, which is why one might have a filtered air inlet to the crankcase in a "real" PCV system.

DerekJ

Luke Skywalker

Offline

John,

I don't think I understand that correctly. In the Healey standard system the crankcase breather tube is connected to the air filter and so is effectively open to atmosphere. In this case I don't see how a vacumn could be created in the crankcase. Even if it was, where is the oil being 'pulled into the engine' being pulled from? The posters issue is oil escaping out not being pulled in.

The purpose of a PCV valve is to regulate the amount of waste gasses vented to the intake mixture in accordance with engine performance. At low revs very little gas is recirculated whilst at full throttle all the gas is expelled through the valve. The regulation of the expulsion of gasses is much more important in modern highly calibrated engines. Modern PCV systems also allow some fresh air to pass into the crankcase before all the waste fumes are expelled via a different circuit. Healeys don't have that.

Getting back to Healeys and the original post, I do not see how installing a PCV valve can have any impact on oil leaks. In fact, if a valve is installed and not properly functioning this could cause a build up in crankcase pressure and a subsequent leak.

I don't think I understand that correctly. In the Healey standard system the crankcase breather tube is connected to the air filter and so is effectively open to atmosphere. In this case I don't see how a vacumn could be created in the crankcase. Even if it was, where is the oil being 'pulled into the engine' being pulled from? The posters issue is oil escaping out not being pulled in.

The purpose of a PCV valve is to regulate the amount of waste gasses vented to the intake mixture in accordance with engine performance. At low revs very little gas is recirculated whilst at full throttle all the gas is expelled through the valve. The regulation of the expulsion of gasses is much more important in modern highly calibrated engines. Modern PCV systems also allow some fresh air to pass into the crankcase before all the waste fumes are expelled via a different circuit. Healeys don't have that.

Getting back to Healeys and the original post, I do not see how installing a PCV valve can have any impact on oil leaks. In fact, if a valve is installed and not properly functioning this could cause a build up in crankcase pressure and a subsequent leak.

RAC68

Darth Vader

Offline

Hi All,

I think I understand Derek’s concern but would contend that the purpose of the PCV was to maintain an appropriate level of vacuum within the intake to allow good performance. Yes, the close of this vent could cause the increase of gaseous pressure within the crank and internal compartments of the engine. However, this condition represents a failure and should be a rare happening if the PCV is kept reasonably clean and sized properly. Even operating with this failure, I would expect that only oil would be lost before the engine condition is noticed through significant increases in billowing smoke from the engine before being turned off.

To put a circle around my thoughts, as I see it, we are using the PCV as an automatic self-regulating vacuum valve that will close to maintain sufficient engine operating vacuum during combustion cycle stages normally low in vacuum production. Although exhaust cleanliness is expected to improve by this implementation, our objective is only to stop producing internal pressures that push oily vapor through openings in the engine, and no more.

Within the limited context of eliminating engine leaks, we only want to reduce internal engine pressure to zero or slightly less. However, since the development of internal engine vapor pressure is highly dependent upon the specific conditions of each engine, the amount of vacuum needed to maintain a zero or slightly lower pressure will vary and, with the lack of available specific PCV detail, sizing becomes a matter of guess and experiment with no single unit satisfying all Healey engine conditions.

Although we must depend upon intuition, logic, and experimentation to make a PCV selection, the number of factors available to consider are relatively small. We need a valve that will:

Additionally, I will be using the Oil Catch Can presented in an earlier post to eliminate the introduction of oily vapor into my intake manifold.

So, what PCV should I start with? Since others have used and found the PV770 to perform satisfactorily, my intention is to acquire and test this unit for my first experiment. Following the outcome of its performance, I will look to find and test a unit designed for a small 4-cylinder engine and would welcome any suggestions. Again, I don’t believe that all Big Healey engines are identical in construction and operation so there may not be a universal solution to this valve. However, out bottom-line objective is relatively simplistic and not as complicated as improving the emissions profile of your engines.

Ray (64BJ8P1)

I think I understand Derek’s concern but would contend that the purpose of the PCV was to maintain an appropriate level of vacuum within the intake to allow good performance. Yes, the close of this vent could cause the increase of gaseous pressure within the crank and internal compartments of the engine. However, this condition represents a failure and should be a rare happening if the PCV is kept reasonably clean and sized properly. Even operating with this failure, I would expect that only oil would be lost before the engine condition is noticed through significant increases in billowing smoke from the engine before being turned off.

To put a circle around my thoughts, as I see it, we are using the PCV as an automatic self-regulating vacuum valve that will close to maintain sufficient engine operating vacuum during combustion cycle stages normally low in vacuum production. Although exhaust cleanliness is expected to improve by this implementation, our objective is only to stop producing internal pressures that push oily vapor through openings in the engine, and no more.

Within the limited context of eliminating engine leaks, we only want to reduce internal engine pressure to zero or slightly less. However, since the development of internal engine vapor pressure is highly dependent upon the specific conditions of each engine, the amount of vacuum needed to maintain a zero or slightly lower pressure will vary and, with the lack of available specific PCV detail, sizing becomes a matter of guess and experiment with no single unit satisfying all Healey engine conditions.

Although we must depend upon intuition, logic, and experimentation to make a PCV selection, the number of factors available to consider are relatively small. We need a valve that will:

- Pull a slight vacuum after an accelerated acceleration. Since our objective is to maintain a minimal amount of lower-then-atmospheric pressure within the engine, I suspect (but am only guessing) a PCV used in a small 4-cylinder engine would be sufficient.

- Easily install within the tube size installed onto the valve cover “T”.

- Not deter from the performance of the brake servo.

Additionally, I will be using the Oil Catch Can presented in an earlier post to eliminate the introduction of oily vapor into my intake manifold.

So, what PCV should I start with? Since others have used and found the PV770 to perform satisfactorily, my intention is to acquire and test this unit for my first experiment. Following the outcome of its performance, I will look to find and test a unit designed for a small 4-cylinder engine and would welcome any suggestions. Again, I don’t believe that all Big Healey engines are identical in construction and operation so there may not be a universal solution to this valve. However, out bottom-line objective is relatively simplistic and not as complicated as improving the emissions profile of your engines.

Ray (64BJ8P1)

Offline

You are correct that in the Healey standard [6-cylinder] system the breather tube is connected to the air filter. There may be a slight vacuum caused by the minor pressure drop through the air filter, but the crankcase is effectively at atmospheric pressure. There is no preferential flow path for the oil, so some leaks out.John,

I don't think I understand that correctly. In the Healey standard system the crankcase breather tube is connected to the air filter and so is effectively open to atmosphere. In this case I don't see how a vacumn could be created in the crankcase. Even if it was, where is the oil being 'pulled into the engine' being pulled from? The posters issue is oil escaping out not being pulled in.

The purpose of a PCV valve is to regulate the amount of waste gasses vented to the intake mixture in accordance with engine performance. At low revs very little gas is recirculated whilst at full throttle all the gas is expelled through the valve. The regulation of the expulsion of gasses is much more important in modern highly calibrated engines. Modern PCV systems also allow some fresh air to pass into the crankcase before all the waste fumes are expelled via a different circuit. Healeys don't have that.

Getting back to Healeys and the original post, I do not see how installing a PCV valve can have any impact on oil leaks. In fact, if a valve is installed and not properly functioning this could cause a build up in crankcase pressure and a subsequent leak.

When installing a PCV valve, the breather tube is now connected to the intake manifold, which has a significant vacuum when the engine is running. Except at idle, when the PCV valve is mostly closed, this vacuum draws on the crankcase, creating a vacuum in the crankcase. The gasses being drawn through the PCV valve into the intake manifold come from three sources: blowby, the oil filler cap vent (unfiltered), and leakage by the seals (rear seal, if any, timing gear cover seal, dipstick seal, and distributor seal, also unfiltered). Where these leak oil, the incoming air helps keep the oil from leaking out.

You are correct that in a modern engine, there is a filtered air inlet to the crankcase. This reduces the vacuum in the crankcase so that unfiltered air is not drawn in past the seals.

Offline

Hi Folks, I have read thru this thread rather quickly so please forgive me if I restate the obvious or am not completely on subject. But there are a few things I'd like to add. The hose that is stuck into the air filters on cars that have a Crankcase Ventilation System or a Positive Crankcase Ventilation System (they are two distinctly different configurations) is definately for the purpose of bringing air into the crankcase. It is put into the air filter as an attempt to only draw in filtered air. This is so as to not bring in "dirty air" that would easily contaminate the oil in the oil pan. In the old days of road draft tubes, the air was usually allowed in thru a vented cap and of coarse "vented" to the atmosphere thru the road draft tube. The tubes length and usually the angle of the cut on the end of the tube was calculated to allow the best opportunity for the air passing beneath the vehicle to draw the air out of the crankcase. Once we enclose this system we have a "Positive Crankcase Ventilation System" and as such the movement of air thru the crankcase has to be managed.

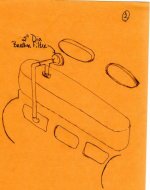

One of the things to note is that even if we create a vacuum in this system, this is not the vacuum that operates the power brakes. We have two systems here. The intake stream, which is the air that is being drawn thru the carburettors down the intake manifold into the cylinders and OUT THE EXHAUST VALVE AND PIPE. This is totally separate from the void in the crankcase where the crankshaft is rotating. The only connection would be any usually small amount (on a good engine) of blowby that is getting past the piston rings. If anything this would create pressure in the crankcase if it was not vented. (hence initially a road draft tube). Any sensation of a vacuum which might be felt at the oil fill cap by your hand is not really a vacuum as much as it is a suction. Or let me says it is not a suction that would be used for the power brakes. Suction meaning that it is pulling air thru there but it is not really creating something that is less than atmosphere, just moving air. Of coarse to draw air thru there you have to be sucking it from somewhere. That point is the connection where you connected the hose and PCV to the intake manifold. If you where to close off the PCV valve you would again be creating pressure in the crankcase. I believe a PCV system can be used on a Healey for two purposes. 1st, it is good for the environment, even modest as that may seem, and 2nd it is good for our immediate environment as it would tend to reduce some engine oil smell as we enjoy our Healeys. It might go along way towards the wife enjoying our Healeys more. And then maybe a third is that a cleaner atmosphere in the crankcase minutely may extend engine life. I believe a PCV system on our Healeys or any car for that matter should only be used if it is Managed well. Recognizing that a PCV valve is closed at some times of the operation of the engine, then at those times the crankcase is pressurized. Ideally that should not be the case. That's when you will create and exasperate leaks. When the PCV valve is open and this then is when the intake stream is allowed to let IT'S vacuum to pull air thru the crankcase then I believe there should be an equivalent area of openning somewhere in the crankcase to allow the volume of air that the hose and PCV valve can handle to move the air freely. This likely spot on the Healey would be the vented oil fill cap. But I do not believe this to be the best configuration because it provides both opennings to be at the top of the engine with free unrestricted air between both opennings and nothing to cause ventilation into the lower part of the crankcase. For this reason I have found that so far we have not come up with a really good configuration for the application of a PCV valve on the Big Healey 6 cyl. Since I wrote of this last, and I didn't have any miles on my new engine I have now spent at least the past summer driving my Healey. And I did change my crankcase ventilation system but did not use a PCV valve or system. I took a modest step to see how it would work and it has worked very well. All I did was to remove the hose from the "TEE" fitting at the rear of the valve cover and the rear carb. I then installed a small 2" dia K&N filter on the "TEE". I left the hose between the "TEE" and the side tappet cover in place. This is the way I drove the car all summer. What I noticed is that 1. the car worked flawlessley. I starts quickly, revs freely, and idles as 400 rpms. 2. the rear carb is as clean as the front carb with no residual oiling or sooting. and 3. I have no crankcase leak or spotting on the ground when parked. Not even from the rear main seal area.

I attribute all this to a free flowing crankcase, with no undo pressure. Even though this is not ideal, since the system is still pretty much in tack, I believe removing the hose to the carb allowed enough of a reduction of restriction to help the system. In my earlier post, I called that hose a two way street. And very restricting.

As a side note, I expected that small K&N filter to become saturated with oil and at the least start to drip. In the whole summer of driving, about 1500 miles, it did not. But near the end of the driving season, maybe late October, I notice a small drop of oil, about the size of a quarter under

the car about below the rear main seal. Each time I parked it. The K&N filter is not wet to the touch, and it is not dripping but it is discoloured. the element is very dark where when installed it was very light in colour. I am wondering if as the filter became saturated with oil that the pressure in the crankcase is increasing and thereby starting to find its way out at the rear main seal. This spring when I replace the K&N filter we will see if the small drop stops. Pardon my rambling, maybe some will help. Dave.

One of the things to note is that even if we create a vacuum in this system, this is not the vacuum that operates the power brakes. We have two systems here. The intake stream, which is the air that is being drawn thru the carburettors down the intake manifold into the cylinders and OUT THE EXHAUST VALVE AND PIPE. This is totally separate from the void in the crankcase where the crankshaft is rotating. The only connection would be any usually small amount (on a good engine) of blowby that is getting past the piston rings. If anything this would create pressure in the crankcase if it was not vented. (hence initially a road draft tube). Any sensation of a vacuum which might be felt at the oil fill cap by your hand is not really a vacuum as much as it is a suction. Or let me says it is not a suction that would be used for the power brakes. Suction meaning that it is pulling air thru there but it is not really creating something that is less than atmosphere, just moving air. Of coarse to draw air thru there you have to be sucking it from somewhere. That point is the connection where you connected the hose and PCV to the intake manifold. If you where to close off the PCV valve you would again be creating pressure in the crankcase. I believe a PCV system can be used on a Healey for two purposes. 1st, it is good for the environment, even modest as that may seem, and 2nd it is good for our immediate environment as it would tend to reduce some engine oil smell as we enjoy our Healeys. It might go along way towards the wife enjoying our Healeys more. And then maybe a third is that a cleaner atmosphere in the crankcase minutely may extend engine life. I believe a PCV system on our Healeys or any car for that matter should only be used if it is Managed well. Recognizing that a PCV valve is closed at some times of the operation of the engine, then at those times the crankcase is pressurized. Ideally that should not be the case. That's when you will create and exasperate leaks. When the PCV valve is open and this then is when the intake stream is allowed to let IT'S vacuum to pull air thru the crankcase then I believe there should be an equivalent area of openning somewhere in the crankcase to allow the volume of air that the hose and PCV valve can handle to move the air freely. This likely spot on the Healey would be the vented oil fill cap. But I do not believe this to be the best configuration because it provides both opennings to be at the top of the engine with free unrestricted air between both opennings and nothing to cause ventilation into the lower part of the crankcase. For this reason I have found that so far we have not come up with a really good configuration for the application of a PCV valve on the Big Healey 6 cyl. Since I wrote of this last, and I didn't have any miles on my new engine I have now spent at least the past summer driving my Healey. And I did change my crankcase ventilation system but did not use a PCV valve or system. I took a modest step to see how it would work and it has worked very well. All I did was to remove the hose from the "TEE" fitting at the rear of the valve cover and the rear carb. I then installed a small 2" dia K&N filter on the "TEE". I left the hose between the "TEE" and the side tappet cover in place. This is the way I drove the car all summer. What I noticed is that 1. the car worked flawlessley. I starts quickly, revs freely, and idles as 400 rpms. 2. the rear carb is as clean as the front carb with no residual oiling or sooting. and 3. I have no crankcase leak or spotting on the ground when parked. Not even from the rear main seal area.

I attribute all this to a free flowing crankcase, with no undo pressure. Even though this is not ideal, since the system is still pretty much in tack, I believe removing the hose to the carb allowed enough of a reduction of restriction to help the system. In my earlier post, I called that hose a two way street. And very restricting.

As a side note, I expected that small K&N filter to become saturated with oil and at the least start to drip. In the whole summer of driving, about 1500 miles, it did not. But near the end of the driving season, maybe late October, I notice a small drop of oil, about the size of a quarter under

the car about below the rear main seal. Each time I parked it. The K&N filter is not wet to the touch, and it is not dripping but it is discoloured. the element is very dark where when installed it was very light in colour. I am wondering if as the filter became saturated with oil that the pressure in the crankcase is increasing and thereby starting to find its way out at the rear main seal. This spring when I replace the K&N filter we will see if the small drop stops. Pardon my rambling, maybe some will help. Dave.

Attachments

Bob_Spidell

Yoda

Offline

re: "... This spring when I replace the K&N filter ..."

Why replace it? They're meant to be cleaned and reused (that's half the marketing; that and 'better flow').

Why replace it? They're meant to be cleaned and reused (that's half the marketing; that and 'better flow').

Offline

I've been using this one from Toms Import Toys. https://www.tomsimport.com/new/parts/parts.asp?sect=35&new=1Hi Bob, I'm not sure the one I've been using is washable. These little ones are not the same as the oil impregnated ones used on Carburettors. At least I don't think so. But I will look into it pretty soon and report back. Dave.

Offline

Mine is suppose to be washable.Hi Bob, I'm not sure the one I've been using is washable. These little ones are not the same as the oil impregnated ones used on Carburettors. At least I don't think so. But I will look into it pretty soon and report back. Dave.

DerekJ

Luke Skywalker

Offline

From a subject I originally had no interest in I must say I have enjoyed researching crankcase ventilation and reading all the comments about this pesky PCV valve! I'm going to summarise my understanding of the situation in a distillation of everything that's been posted and what I've read elsewhere.

1. A standard Healey has a crankcase ventilation system but not the same as that which is now known as a Positive Crankcase Ventilation system as first introduced during the 1960s.

2. The Healey system is basically the original 'draft' system except that for environmental reasons the gasses from the crankcase (and valve cover) are redirected into the air filter (then the intake manifold) instead of into the slipstream beneath the car. (Interestingly the car I bought 3 years ago with an engine built by DWR and with an ITG air filter was rather naughtily using the old system and venting to the slipstream. I could definitely detect a slight smell from that, which has now gone with the addition of a catch tank and filter).

3. The 1960's PCV system circulates air through the crankcase. Air is sucked out of the crankcase into the manifold behind the butterfly. Air is sucked into the crankcase from the air filter intake via a completely different route. The Healey does not have this separate direct air intake into the crankcase and its crankcase to air filter connection is to withdraw air not suck air in. In the Healey system air is drawn into the crankcase through the oil filler cap breather and probably through other air gaps such as at the dipstick.

4 A key part of the 'new' PCV system was a PCV valve. This is to restrict the flow of gasses from the crankcase to manifold when the engine is at idle or running slowly, at which times the engine would be more affected by the inflow of waste gasses. At higher speed operation the valve is fully open with free gas flow. In this system the PCV valve has nothing to do with preventing any oil loss from the crankcase, in fact if anything it would tend to have the opposite effect by retaining a small amount of pressure in the crankcase during low speed operation.

5 Adding a PCV valve to the Healey system is actually a 'bastardisation' of the two systems and does not create a true PCV system (as pointed out by Bob in one of his posts). Instead it seems that the idea is to block up the oil cap breather and better seal the dipstick to prevent any air entering the crankcase from those sources. The theory being that a 'vacuum' (it isn't really one), would be created in the crankcase thereby preventing oil from escaping.

6. In practise it appears that, assuming all other air intakes are blocked, then air might ingress through the rear of the crankcase and/or the seal in the timing chain area. This incoming air inflow being at the places where we can normally expect some oil seepage out.

7 The PCV valve itself really has nothing to do with preventing the oil loss. In fact if the same connections were made but without the PCV valve it is probable that that the result could be even better as there would be no restriction on outflowing air. I don't know if anybody has tried this but presumably if they did they might find that the engine does not run as well at low speeds. Anyone fancy trying it?

In summary, my own opinion is that it doesn't seem worth the effort to bastardise the system just to perhaps prevent some minor oil loss. In doing so you could be introducing other complications such as fitting the wrong size valve (there are none designed for a Healey engine) and drawing air in through seals that are meant to keep oil from escaping the engine not let air into it.

More comments welcomed!

1. A standard Healey has a crankcase ventilation system but not the same as that which is now known as a Positive Crankcase Ventilation system as first introduced during the 1960s.

2. The Healey system is basically the original 'draft' system except that for environmental reasons the gasses from the crankcase (and valve cover) are redirected into the air filter (then the intake manifold) instead of into the slipstream beneath the car. (Interestingly the car I bought 3 years ago with an engine built by DWR and with an ITG air filter was rather naughtily using the old system and venting to the slipstream. I could definitely detect a slight smell from that, which has now gone with the addition of a catch tank and filter).

3. The 1960's PCV system circulates air through the crankcase. Air is sucked out of the crankcase into the manifold behind the butterfly. Air is sucked into the crankcase from the air filter intake via a completely different route. The Healey does not have this separate direct air intake into the crankcase and its crankcase to air filter connection is to withdraw air not suck air in. In the Healey system air is drawn into the crankcase through the oil filler cap breather and probably through other air gaps such as at the dipstick.

4 A key part of the 'new' PCV system was a PCV valve. This is to restrict the flow of gasses from the crankcase to manifold when the engine is at idle or running slowly, at which times the engine would be more affected by the inflow of waste gasses. At higher speed operation the valve is fully open with free gas flow. In this system the PCV valve has nothing to do with preventing any oil loss from the crankcase, in fact if anything it would tend to have the opposite effect by retaining a small amount of pressure in the crankcase during low speed operation.

5 Adding a PCV valve to the Healey system is actually a 'bastardisation' of the two systems and does not create a true PCV system (as pointed out by Bob in one of his posts). Instead it seems that the idea is to block up the oil cap breather and better seal the dipstick to prevent any air entering the crankcase from those sources. The theory being that a 'vacuum' (it isn't really one), would be created in the crankcase thereby preventing oil from escaping.

6. In practise it appears that, assuming all other air intakes are blocked, then air might ingress through the rear of the crankcase and/or the seal in the timing chain area. This incoming air inflow being at the places where we can normally expect some oil seepage out.

7 The PCV valve itself really has nothing to do with preventing the oil loss. In fact if the same connections were made but without the PCV valve it is probable that that the result could be even better as there would be no restriction on outflowing air. I don't know if anybody has tried this but presumably if they did they might find that the engine does not run as well at low speeds. Anyone fancy trying it?

In summary, my own opinion is that it doesn't seem worth the effort to bastardise the system just to perhaps prevent some minor oil loss. In doing so you could be introducing other complications such as fitting the wrong size valve (there are none designed for a Healey engine) and drawing air in through seals that are meant to keep oil from escaping the engine not let air into it.

More comments welcomed!

ttrotter

Member

Offline

Derek, this is a fine summation of a great thread and I do appreciate everyone's contribution to my continuing education.

At this point, I have decided NOT to install the pcv valve.

Sounds as if the small crankcase vent filter that Dave and others use may at least help me keep the rear carb a lot cleaner. The other alternative would be the installation of Ray's oil catch can. I made one last summer and used it for maybe 500 miles. I did not catch any visible oil, but I suspect I just did not give it enough time/miles. I know I trapped some noxious fumes as evidenced by the steel mesh color and sticky feel. I'll go back to that this spring and see what happens.

As far as the irritating minor oil drip--well, it's a Healey

At this point, I have decided NOT to install the pcv valve.

Sounds as if the small crankcase vent filter that Dave and others use may at least help me keep the rear carb a lot cleaner. The other alternative would be the installation of Ray's oil catch can. I made one last summer and used it for maybe 500 miles. I did not catch any visible oil, but I suspect I just did not give it enough time/miles. I know I trapped some noxious fumes as evidenced by the steel mesh color and sticky feel. I'll go back to that this spring and see what happens.

As far as the irritating minor oil drip--well, it's a Healey

Bob_Spidell

Yoda

Offline

I'll (mildly) dispute a couple items:

1) My BJ8 engine does pull a 'vacuum' at idle. If you put your hand over the oil filler hole it feels just like putting your hand on the nozzle of a (weak) vacuum cleaner. I believe this is because the PCV valve doesn't seal completely when closed; it's all metal and there's plenty of leakage. This is not 'suction' due to air flow; when you cover a passage guess what? There is no air flow (response to an earlier post).

2) I've tracked mileage/MPG/oil consumption pretty closely on my annual 3-4K mile Healey trips (mostly highway/backroad driving); oil consumption went from 1qt/800 miles to less than half that after I installed the valve, with no other significant changes to the engine. The cloud of blue smoke I got on deceleration went from embarrassing to negligible.

Then engine is a bit lumpy at idle, but I didn't notice a difference when I first installed the valve, and haven't driven any other BJ8s since. Since the BJ8 has a 'hotter' cam that is often retrofitted to earlier cars for performance this does not surprise me (actually, my cam is a Crower regrind--their mildest--but I think it's pretty close to stock).

It remains to be seen if there is buildup on the intake valves due to blowby in the manifold. This can be a problem with any PCV valve-equipped engine as you're venting 'dirty' gasses into the manifold; I've seen it on my Ranger (check out the Audi message boards; lots of people complaining about expensive manifold cleanings due to direct injection).

1) My BJ8 engine does pull a 'vacuum' at idle. If you put your hand over the oil filler hole it feels just like putting your hand on the nozzle of a (weak) vacuum cleaner. I believe this is because the PCV valve doesn't seal completely when closed; it's all metal and there's plenty of leakage. This is not 'suction' due to air flow; when you cover a passage guess what? There is no air flow (response to an earlier post).

2) I've tracked mileage/MPG/oil consumption pretty closely on my annual 3-4K mile Healey trips (mostly highway/backroad driving); oil consumption went from 1qt/800 miles to less than half that after I installed the valve, with no other significant changes to the engine. The cloud of blue smoke I got on deceleration went from embarrassing to negligible.

Then engine is a bit lumpy at idle, but I didn't notice a difference when I first installed the valve, and haven't driven any other BJ8s since. Since the BJ8 has a 'hotter' cam that is often retrofitted to earlier cars for performance this does not surprise me (actually, my cam is a Crower regrind--their mildest--but I think it's pretty close to stock).

It remains to be seen if there is buildup on the intake valves due to blowby in the manifold. This can be a problem with any PCV valve-equipped engine as you're venting 'dirty' gasses into the manifold; I've seen it on my Ranger (check out the Audi message boards; lots of people complaining about expensive manifold cleanings due to direct injection).

Bob_Spidell

Yoda

Offline

I'll add that I installed a valve not to cure oil leaks or the smoking; I installed it because I installed K&N air filters which didn't have a port for the blow-by hose. Also, I'd previously installed foam filters which did have a vent, though the adapter was narrower (3/8" maybe), and right angle and I ruined a valve cover trying to stop oil from seeping out from under it due to pressure buildup. The other effects of the PCV were unexpected but welcome.

I'm thankful for the K&Ns every time I get caught in a dust storm; they may not be the best for filtering air but they gotta be better than the stock grasshopper stoppers.

I'm thankful for the K&Ns every time I get caught in a dust storm; they may not be the best for filtering air but they gotta be better than the stock grasshopper stoppers.

DerekJ

Luke Skywalker

Offline

Bob,

That is interesting. Did you also block up the oil filler breather and seal the dipstick? If you removed the valve do you think this would affect the low down performance of the engine? As mentioned I vent mine to an alloy catch tank which avoids the re-circulation issue.

That is interesting. Did you also block up the oil filler breather and seal the dipstick? If you removed the valve do you think this would affect the low down performance of the engine? As mentioned I vent mine to an alloy catch tank which avoids the re-circulation issue.

Bob_Spidell

Yoda

Offline

re: "Did you also block up the oil filler breather and seal the dipstick?"

Yep.

re: "If you removed the valve do you think this would affect the low down performance of the engine?"

Presume engine would run like crap since it would essentially be a massive intake leak. I didn't notice any differences in engine behavior after installing the PCV valve when I installed the K&N filters. Any effect from the air filters would be slight and you'd need a dyno to tell the difference.

Hope everyone understands I'm not advocating installing a PCV or not; I'm just reporting my experiences with it. I hadn't expected the reduced oil consumption/loss, or the reduced smoking, so no confirmation bias.

Yep.

re: "If you removed the valve do you think this would affect the low down performance of the engine?"

Presume engine would run like crap since it would essentially be a massive intake leak. I didn't notice any differences in engine behavior after installing the PCV valve when I installed the K&N filters. Any effect from the air filters would be slight and you'd need a dyno to tell the difference.

Hope everyone understands I'm not advocating installing a PCV or not; I'm just reporting my experiences with it. I hadn't expected the reduced oil consumption/loss, or the reduced smoking, so no confirmation bias.

RAC68

Darth Vader

Offline

Hi Dave/All,

After reading your post prior to your summary, my impression is that you were describing a very close-to-true Positive Crankcase Ventilation system. Although I appreciate this direction and feel it could hold more promising result, it is not the way I had planned to try.

At present, I only see the PCV as a means of managing vacuum within the operational context of the engine. Although I agree there is potential to suck dirt from around the mains when pulling a vacuum in the engine, I think the amount or type of contaminants brought in would be infinitesimal if the internal pressure is kept to a level only marginally below atmospheric. My objective is to only apply sufficient assist to the present technology (seals and reverse screw main) and have it perform sufficiently to eliminate oil leakage.

My first try sizing a PCV will be to acquire and test a PV770 as used by Steve suggested. I plan to install the PCV after the Oil Catch Can and initially vent it through a “Y” fitting along with the brake servo. If all goes as expected, I intend to acquire and install a PCV from a smaller engine (assuming a small 4-cylinder PCV would manage less of a vacuum draw then the PV770).

If all performs well, I would consider eliminating the “Y” fitting and providing a separate manifold take-off for the PCV and servo with the PCV tapped into the center of the manifold. Good idea or bad?

Well, that’s it for now since the snow and ice will keep everything put, it will probably be April before I start.

Ray (64BJ8P1)

After reading your post prior to your summary, my impression is that you were describing a very close-to-true Positive Crankcase Ventilation system. Although I appreciate this direction and feel it could hold more promising result, it is not the way I had planned to try.

At present, I only see the PCV as a means of managing vacuum within the operational context of the engine. Although I agree there is potential to suck dirt from around the mains when pulling a vacuum in the engine, I think the amount or type of contaminants brought in would be infinitesimal if the internal pressure is kept to a level only marginally below atmospheric. My objective is to only apply sufficient assist to the present technology (seals and reverse screw main) and have it perform sufficiently to eliminate oil leakage.

My first try sizing a PCV will be to acquire and test a PV770 as used by Steve suggested. I plan to install the PCV after the Oil Catch Can and initially vent it through a “Y” fitting along with the brake servo. If all goes as expected, I intend to acquire and install a PCV from a smaller engine (assuming a small 4-cylinder PCV would manage less of a vacuum draw then the PV770).

If all performs well, I would consider eliminating the “Y” fitting and providing a separate manifold take-off for the PCV and servo with the PCV tapped into the center of the manifold. Good idea or bad?

Well, that’s it for now since the snow and ice will keep everything put, it will probably be April before I start.

Ray (64BJ8P1)