Rut

Obi Wan

Offline

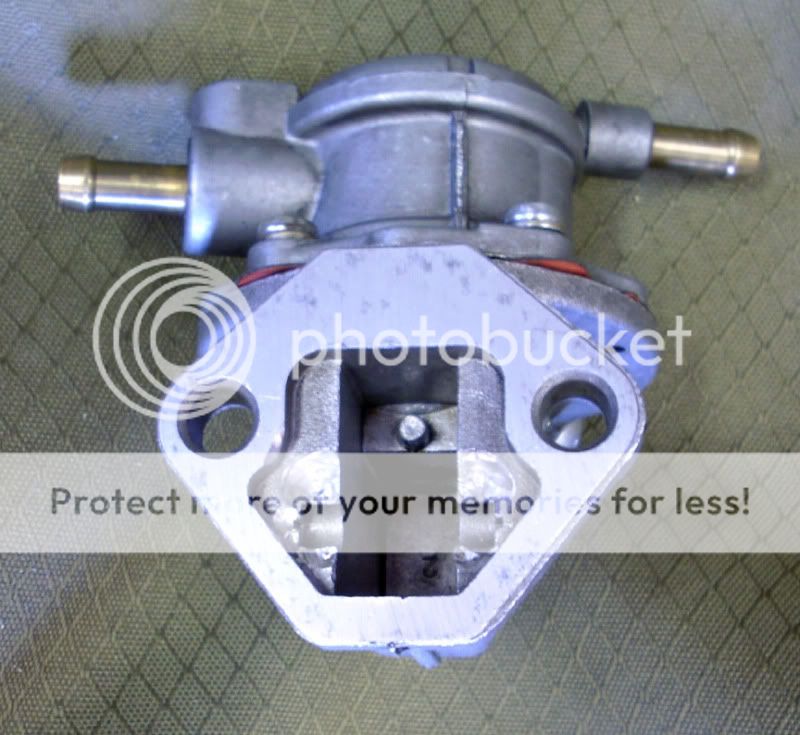

How about a 1275 PCV from a later model? I thought about finding a way to add a little more restriction to my air filter material (it's dry, new foam) and see if that would pull a little negative pressure. I don't know who the mfg of the oval, chrome, Weber air filter is, but I've never seen this type before...not K&N for sure.

Rut

Rut

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>