On my '56 BN2 four speed--Using a separate battery to test the OD solenoid, it appears less than powerful enough to engage the OD. It appears to have plenty of strength on 24 volts (just a test--not suggesting I carry a spare battery simply for the solenoid). How do I determine if the solenoid is working properly? How much pull is necessary to engage the OD? What goes bad to cause a solenoid to fail?

-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Overdrive solenoid--How do I diagnose weakness?

- Thread starter jayarbee

- Start date

Patton

Jedi Warrior

Offline

Lots of solenoid wisdom here....

https://www.serve.com/AHCA/technical/solenoid.htm

https://www.serve.com/AHCA/technical/solenoid.htm

Offline

Jay',

First, get a copy of, or look in, your Austin-Healey service manual. Be sure you get the BN-2 supplement because there are some differences between the BN-1 overdrive circut and the BN-2 system. There is a simple and comprehensive troubleshooting guide you can use to pinpoint the problem.

Second, there are two coils (a closing coil and a holding coil) in the overdrive solenoid, both are energized initially and then a set of points is opened when the core

is magnitized, moving the plunger, and cutting out the closing coil so the current requirement drops off. It keeps the coil from overheating. If one of your coils is shorted the solenoid would be weak. I would not put 24 volts through your solenoid again. I work with 24 volt systems in aircraft. The speed with which smoke can be released from wiring is frighteningly faster with 24 volts than with 12. It is designed to work on 12 volts. It must be strong enough to move the lever on the gearbox. I can't tell you how much force that takes, but if it doesn't move the lever you probably have a bad solenoid (assuming no problems inside the gearbox). A good loud clack is what you should hear when the solenoid is engaged. If the points are not closing properly you would only have the holding coil trying to operate the magnet, again, it would be weak.

Hope this helps.

Jon Robbins

Jon Robbins

First, get a copy of, or look in, your Austin-Healey service manual. Be sure you get the BN-2 supplement because there are some differences between the BN-1 overdrive circut and the BN-2 system. There is a simple and comprehensive troubleshooting guide you can use to pinpoint the problem.

Second, there are two coils (a closing coil and a holding coil) in the overdrive solenoid, both are energized initially and then a set of points is opened when the core

is magnitized, moving the plunger, and cutting out the closing coil so the current requirement drops off. It keeps the coil from overheating. If one of your coils is shorted the solenoid would be weak. I would not put 24 volts through your solenoid again. I work with 24 volt systems in aircraft. The speed with which smoke can be released from wiring is frighteningly faster with 24 volts than with 12. It is designed to work on 12 volts. It must be strong enough to move the lever on the gearbox. I can't tell you how much force that takes, but if it doesn't move the lever you probably have a bad solenoid (assuming no problems inside the gearbox). A good loud clack is what you should hear when the solenoid is engaged. If the points are not closing properly you would only have the holding coil trying to operate the magnet, again, it would be weak.

Hope this helps.

Jon Robbins

Jon Robbins

Re: Overdrive solenoid--How do I diagnose weakness

Thanks. I opened the top cover and discovered the internal switch and deduced what you said. It appears both coils are good, as there is a definite resistance change when the switch opens. The solenoid was able to support a three pound weight during a test I devised. I think the solution will be in the adjustment. The link to the AHCA article on overdrive solenoids was very helpful.

Thanks. I opened the top cover and discovered the internal switch and deduced what you said. It appears both coils are good, as there is a definite resistance change when the switch opens. The solenoid was able to support a three pound weight during a test I devised. I think the solution will be in the adjustment. The link to the AHCA article on overdrive solenoids was very helpful.

Re: Overdrive solenoid--How do I diagnose weakness

Final update: I adjusted the actuation lever as directed, tested, and discovered that after actuation a little nudge by hand was needed for engagement, as was mentioned in one of the AHCA articles. After re-adjustment all is fine.

Addendum: I recall that my first BN2, in 1964 (when I was 18) had a centrifugal switch in the OD circuit, which would, in combination with the throttle position switch, allow the dashboard switch to be turned off and the OD to still be engaged. When the throttle was pressed the OD would disengage automatically and the effect was like a really quick downshift. The centrifugal switch also prevented the OD from engaging at a low speed. My current OD has a cast boss but was not machined for the switch. Does anyone know the history of the change?

Final update: I adjusted the actuation lever as directed, tested, and discovered that after actuation a little nudge by hand was needed for engagement, as was mentioned in one of the AHCA articles. After re-adjustment all is fine.

Addendum: I recall that my first BN2, in 1964 (when I was 18) had a centrifugal switch in the OD circuit, which would, in combination with the throttle position switch, allow the dashboard switch to be turned off and the OD to still be engaged. When the throttle was pressed the OD would disengage automatically and the effect was like a really quick downshift. The centrifugal switch also prevented the OD from engaging at a low speed. My current OD has a cast boss but was not machined for the switch. Does anyone know the history of the change?

Offline

Re: Overdrive solenoid--How do I diagnose weakness

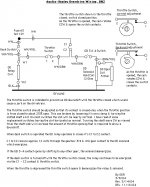

Actually it was the BN1 that had the centrifugal switch plus two control relays. The BN2 was simplified to eliminate the extra "stuff". Your car should not down shift when the dash switch is turned "off", unless the throttle is partially opened. I have attached a schematic of the BN2 overdrive portion of the wiring.

D

Actually it was the BN1 that had the centrifugal switch plus two control relays. The BN2 was simplified to eliminate the extra "stuff". Your car should not down shift when the dash switch is turned "off", unless the throttle is partially opened. I have attached a schematic of the BN2 overdrive portion of the wiring.

D

Attachments

Offline

Re: Overdrive solenoid--How do I diagnose weakness

Hi Jay,

A couple of notes on the OD control valve adjustment:

Control valve adjustment

The control valve located under a brass cap near the front RH side of the OD must be correctly adjusted. Under the brass cap is a spring, a spring follower, a control ball, & a long operating rod. The ball should be 5/16 diameter. The ball lift is what controls shifting. The book method of putting a pin through the RH arm & adjusting the LH operating arm is not a very reliable method of setting the ball lift. Wear in any of the parts will change the required setting from the original pinned arm method.

The most accurate & reliable method of setting the valve lift is:

a- Set control valve ball lift to .030" to .040". Measure with dial indicator. Cap & spring removed. Adjust clamped operating arm. Verify movement with the solenoid plunger, not the arm. I machined an adaptor to fit snugly in the plug hole & to extend high enough to provide a flat surface for a dial depth gage to sit on. I made a cup shaped end for the gage so that it would easily center on the ball.

b- Set solenoid control arm (on solenoid plunger) to .160" drop. Adjust stop or add stop below the plunger if needed to accomplish this. (Arm drop is not the same as plunger drop due to slack in lifter.)

OD operate solenoid

a- The OD soleniod is designed with two electrical coils. The first coil (operate coil) is energized by the OD circuitry. It momentarily draws about 20 amps. As soon as the solenoid is operated, a contact on top of the solenoid opens & transfers current to the second (holding) coil which draws about two amps. If the switching contacts are dirty or damaged, the solenoid will be operating on the holding coil only & will not have enough power to engage the OD. The contacts are located under the top rubber boot.

b- If the switching contacts do not open due to contact problems or the solenoid travel not being adjusted to give a full solenoid stroke, the solenoid will remain energized by the operate coil & burn out quickly.

D

Hi Jay,

A couple of notes on the OD control valve adjustment:

Control valve adjustment

The control valve located under a brass cap near the front RH side of the OD must be correctly adjusted. Under the brass cap is a spring, a spring follower, a control ball, & a long operating rod. The ball should be 5/16 diameter. The ball lift is what controls shifting. The book method of putting a pin through the RH arm & adjusting the LH operating arm is not a very reliable method of setting the ball lift. Wear in any of the parts will change the required setting from the original pinned arm method.

The most accurate & reliable method of setting the valve lift is:

a- Set control valve ball lift to .030" to .040". Measure with dial indicator. Cap & spring removed. Adjust clamped operating arm. Verify movement with the solenoid plunger, not the arm. I machined an adaptor to fit snugly in the plug hole & to extend high enough to provide a flat surface for a dial depth gage to sit on. I made a cup shaped end for the gage so that it would easily center on the ball.

b- Set solenoid control arm (on solenoid plunger) to .160" drop. Adjust stop or add stop below the plunger if needed to accomplish this. (Arm drop is not the same as plunger drop due to slack in lifter.)

OD operate solenoid

a- The OD soleniod is designed with two electrical coils. The first coil (operate coil) is energized by the OD circuitry. It momentarily draws about 20 amps. As soon as the solenoid is operated, a contact on top of the solenoid opens & transfers current to the second (holding) coil which draws about two amps. If the switching contacts are dirty or damaged, the solenoid will be operating on the holding coil only & will not have enough power to engage the OD. The contacts are located under the top rubber boot.

b- If the switching contacts do not open due to contact problems or the solenoid travel not being adjusted to give a full solenoid stroke, the solenoid will remain energized by the operate coil & burn out quickly.

D

Re: Overdrive solenoid--How do I diagnose weakness

Dave, now that you mention the centrifugal switch being on the BN1 I recall that it was my '55 BN1 that had the switch. I only had the BN2 for a year, replacing it with a '58 Chevy Impala because I needed more room for friends. During my stint in the Air Force I acquired a broken engined '55 which I fixed and drove for seven years. It is the one with the centrifugal switch. At the time I figured I was one of the few owners who had figured out the circuit and knew how to make it work. Good memories.

Dave, now that you mention the centrifugal switch being on the BN1 I recall that it was my '55 BN1 that had the switch. I only had the BN2 for a year, replacing it with a '58 Chevy Impala because I needed more room for friends. During my stint in the Air Force I acquired a broken engined '55 which I fixed and drove for seven years. It is the one with the centrifugal switch. At the time I figured I was one of the few owners who had figured out the circuit and knew how to make it work. Good memories.

Healey 100

Jedi Warrior

Offline

Re: Overdrive solenoid--How do I diagnose weakness

I don't have much to add to this discussion except my own discovery that the proper resistance of the coil in the pull-in state (internal solenoid contacts closed) is very, very low, I recall it is way less than an ohm. The resulting high current draw is what enables the solenoid to develop the substantial force needed to engage your overdrive.

This means that even a little extra resistance in the circuit will severely reduce the force from the plunger and will likely prevent engagement of the OD. Extra resistance can appear from poor grounds, bad wiring connections, or worn contacts in either the OD relays or the solenoid points.

My OD suffered for years from intermittant failure to engage. I did not resolve the problem until I spent a lot of time looking at the circuit with an accurate ohm meter. I learned that the points on my solenoid closed and opened fine, but their resistance varied erratically from 0 to as high as 5 ohms. This is because the solenoid contacts were simply too burned from years of breaking a circuit that carries very high current each time the solenoid is engaged.

Clearly, it is important that the linkages are adjusted properly just as the other posters say. But you may find the engagement is still a problem. If your solenoid contacts are weak, clean them up or replace the solenoid/contact assembly.

Good luck!

Bill.

I don't have much to add to this discussion except my own discovery that the proper resistance of the coil in the pull-in state (internal solenoid contacts closed) is very, very low, I recall it is way less than an ohm. The resulting high current draw is what enables the solenoid to develop the substantial force needed to engage your overdrive.

This means that even a little extra resistance in the circuit will severely reduce the force from the plunger and will likely prevent engagement of the OD. Extra resistance can appear from poor grounds, bad wiring connections, or worn contacts in either the OD relays or the solenoid points.

My OD suffered for years from intermittant failure to engage. I did not resolve the problem until I spent a lot of time looking at the circuit with an accurate ohm meter. I learned that the points on my solenoid closed and opened fine, but their resistance varied erratically from 0 to as high as 5 ohms. This is because the solenoid contacts were simply too burned from years of breaking a circuit that carries very high current each time the solenoid is engaged.

Clearly, it is important that the linkages are adjusted properly just as the other posters say. But you may find the engagement is still a problem. If your solenoid contacts are weak, clean them up or replace the solenoid/contact assembly.

Good luck!

Bill.