Hello all

I have an inop overdrive on my Healey. I have satisfied myself all of the electrical components are

functioning correctly.. It used to work flawlessly then slowly became less reliable, now no joy.

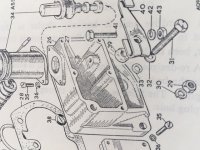

I have found a different set-up under the plunger on the solenoid. The manual calls for a small rubber bumper "stop (rubber)". Part number 27 in the drawing. Mine has a stud with a nut on it. Doesn't look adjustable. I cant find anything like it in the manual. I left the nut off for better view of the stud. Should that rubber bumper be where the stud is??

Anybody have suggestions on how to proceed in adjusting the throw of the solenoid with this finding .

Thanks

Matison

See attached pictures.

I have an inop overdrive on my Healey. I have satisfied myself all of the electrical components are

functioning correctly.. It used to work flawlessly then slowly became less reliable, now no joy.

I have found a different set-up under the plunger on the solenoid. The manual calls for a small rubber bumper "stop (rubber)". Part number 27 in the drawing. Mine has a stud with a nut on it. Doesn't look adjustable. I cant find anything like it in the manual. I left the nut off for better view of the stud. Should that rubber bumper be where the stud is??

Anybody have suggestions on how to proceed in adjusting the throw of the solenoid with this finding .

Thanks

Matison

See attached pictures.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>