John_Progess

Jedi Warrior

Offline

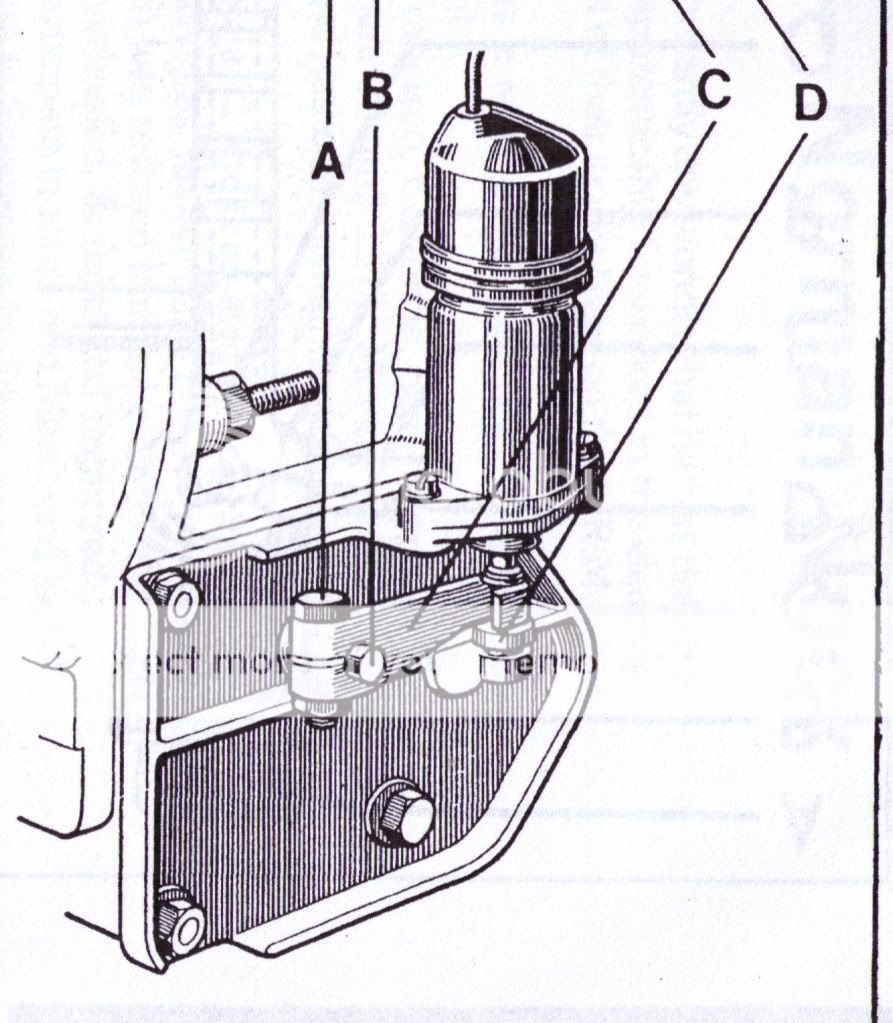

After restoration OD didn't work. AS per suggestions I removed console, tranny tunnel and pushed the lever on right side of tranny down and the OD engaged. I did not get the pinch bolt tight enough so the solonoid lever did not move the operating valve. I adjusted as per the book and the OD worked fine. I was able to engage and disengage. The lever on the right side of tranny was a little off so I adjusted it so it is aligned with the hole. Then I noticed that it engaged but didn't disengage the next time out. Today I started out with the OD switch off and when I shifted into third I felt the OD shift after about 4 seconds or so. Stopped the car, turned the switch on, the solonoid engaged, shut off switch, started out and the OD was still engaged when I shifted into third. Any suggestions would be apreciated. Have a good day!

John

John

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>