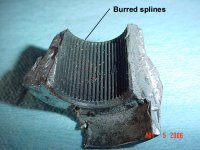

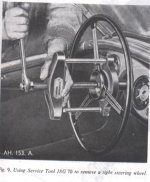

Hi all! I am a newbie and just bought a 62 3000 MK11 BT7. Car has been partially restored and I am trying to remove Steering Wheel. The wheel is a non-adjustable type. I have the horn push, turn signal assy with wiring and stator tube completely removed. Then I was able to remove large 1-1/2 in. nut and cancelling arm. Now the problem.... tapped back of wheel and it freed itself .... but only for about a half inch. Now the wheel itself is moving up and down on what I believe is the inner column. It seems to hit a stop because when pulling and pushing the wheel is very free but will NOT come any further. There is no circlip evident. I cannot see any way to free it. I do not see what it could be hitting up against.Any help would be appreciated. I am going crazy!! Do I need to force it with a puller? Thanks.

-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Non adjustable steering wheel removal

- Thread starter Pete3000

- Start date

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>