Offline

Here's my new and more specific plan for my fuel pump install, based on much feedback from here. Please comment and add/change anything necessary. I've never done this before, so I'm (as always) a bit nervous.

One remaining question is what do I use for the hard fuel line that runs from the pump to the front of the car?

A second question is can/should I run 2 pumps? Can they be run in series with only one turned on? Too much overkill?

1. Parts:

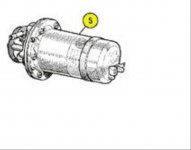

- Pump: Carter, this model (https://shop.oreillyauto.com/productdetai...egoryCode=3339K)

- Soft line: 3/8” @ 8’ or so

- Hard Line: (size/type??) * 8’

- Coarse filter for pre pump

- Fine filter for post pump, near carbs (to install later)

- Fuel line clamps @ 10

2. Paint gas tank

3. Install sender in gas tank

4. Install gas tank and connect sender wires

5. Connect fuel gauge wires behind dash

6. Mount fuel pump

- Cut existing hard line above the rear axle and remove the long run to the front of the car

--- Blow out the remaining short run

- Run short soft line from tank hard line to filter

- Run short soft line from filter to pump

- Mount pump on rear bulkhead

--- It goes somewhere behind the right rear wheel and on the rear bulkhead.

--- You can bolt it up to the rear shelf but watch the hole or drill doesn't twist the rug up as it comes out inside the car.

--- Use some rubber between the pump and car for noise insulation

- Run short soft line from pump to hard line running to the front of the car

--- Hard line runs up the center of the car and crosses to the LH side at the front of the engine bay, with a small amount of length at the end pointing straight up towards the carbs

7. Wire fuel pump to ignition switch

- Run the white wire along the right inner rocker with the rest of the wires to the rear end. Use white wire as it is the correct color for the fuel pump just to keep it "right" incase somebody else works on it in the future.

- On a Bugeye, come out of the trunk where the fuel sender wire comes out.

One remaining question is what do I use for the hard fuel line that runs from the pump to the front of the car?

A second question is can/should I run 2 pumps? Can they be run in series with only one turned on? Too much overkill?

1. Parts:

- Pump: Carter, this model (https://shop.oreillyauto.com/productdetai...egoryCode=3339K)

- Soft line: 3/8” @ 8’ or so

- Hard Line: (size/type??) * 8’

- Coarse filter for pre pump

- Fine filter for post pump, near carbs (to install later)

- Fuel line clamps @ 10

2. Paint gas tank

3. Install sender in gas tank

4. Install gas tank and connect sender wires

5. Connect fuel gauge wires behind dash

6. Mount fuel pump

- Cut existing hard line above the rear axle and remove the long run to the front of the car

--- Blow out the remaining short run

- Run short soft line from tank hard line to filter

- Run short soft line from filter to pump

- Mount pump on rear bulkhead

--- It goes somewhere behind the right rear wheel and on the rear bulkhead.

--- You can bolt it up to the rear shelf but watch the hole or drill doesn't twist the rug up as it comes out inside the car.

--- Use some rubber between the pump and car for noise insulation

- Run short soft line from pump to hard line running to the front of the car

--- Hard line runs up the center of the car and crosses to the LH side at the front of the engine bay, with a small amount of length at the end pointing straight up towards the carbs

7. Wire fuel pump to ignition switch

- Run the white wire along the right inner rocker with the rest of the wires to the rear end. Use white wire as it is the correct color for the fuel pump just to keep it "right" incase somebody else works on it in the future.

- On a Bugeye, come out of the trunk where the fuel sender wire comes out.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>