Offline

I'm looking for a good website that chronicles the removal & replacement of GT body panels.

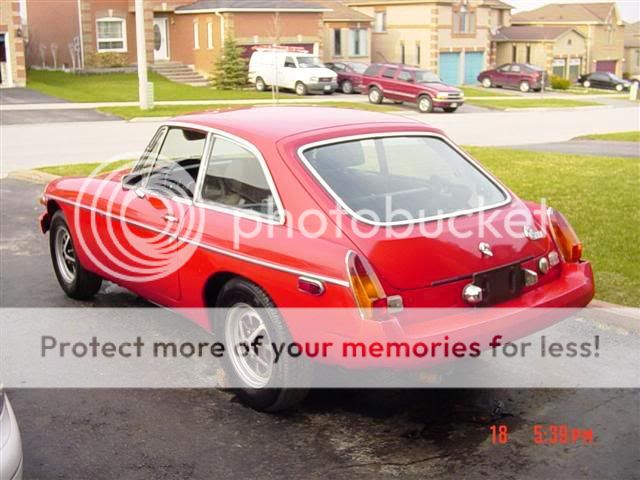

What the car needs it this:

Hood - I'll get a new or used one.

Lower Fenders - I'll look for used unless patching is recommended.

Inner & outer rockers

Castles

Rear doglegs

Front half of passenger floor.

Passenger jacking point.

The trunk floor is OK but needs a few small holes patched.

I don't know what I am in for but willing to learn & try.

My first worry is how to support the car while cutting out the bad and welding in the good.

MG tip of the day. Don't park your car on the grass for 10 years.

What the car needs it this:

Hood - I'll get a new or used one.

Lower Fenders - I'll look for used unless patching is recommended.

Inner & outer rockers

Castles

Rear doglegs

Front half of passenger floor.

Passenger jacking point.

The trunk floor is OK but needs a few small holes patched.

I don't know what I am in for but willing to learn & try.

My first worry is how to support the car while cutting out the bad and welding in the good.

MG tip of the day. Don't park your car on the grass for 10 years.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>