-

Hi Guest!

Hi Guest!

You can help ensure that British Car Forum (BCF) continues to provide a great place to engage in the British car hobby! If you find BCF a beneficial community, please consider supporting our efforts with a subscription.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Loctite for front shock bolts

- Thread starter steveg

- Start date

Bob_Spidell

Yoda

Offline

I've used blue Locktite with hardened flatwashers (only) with bolts torqued to 35 ft-lbs for many years and miles and never had one come loose.

Offline

I've used blue Locktite with hardened flatwashers (only) with bolts torqued to 35 ft-lbs for many years and miles and never had one come loose.

Thanks, Bob - will give that a go.

Offline

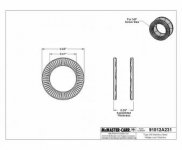

"Spot-facing" the shock also helps. The surface is uneven and this takes care of that problem. I also did the rear shocks the same way. I had to use AN, "aircraft spec" washers because the standard hardware stuff wouldn't work.Thanks, Bob - will give that a go.

Attachments

Offline

Steve,Patrick,

The pictures show a thin and thick washer. Could you explain a little more?

The thin washer is the "aircraft quality" one and the washer on top of it is a standard lock washer. A friend on mine has a special cutting bit & drill press to cut the shock metal casting and in doing so it removes the imperfections and irregularities on the shock metal thereby creating a perfect surface for the shock bolt & washers to "seat" against the surface. I can provide more detailed info when my friend gets back into town showing the equipment we used if you would like that too?

Offline

Steve,

The thin washer is the "aircraft quality" one and the washer on top of it is a standard lock washer. A friend on mine has a special cutting bit & drill press to cut the shock metal casting and in doing so it removes the imperfections and irregularities on the shock metal thereby creating a perfect surface for the shock bolt & washers to "seat" against the surface. I can provide more detailed info when my friend gets back into town showing the equipment we used if you would like that too?

Patrick,

Not necessary. Thank you for the offer.

My setup's a little different as I have a tube shock setup (homemade - similar principle to Udo's) using long bolts through the stanchions. One of these came loose for the first time in 10 years. I had been using belleville washers under the bolt heads and had had no problem but switched to grade-8 split ring washers and one of those came loose.

Since your setup relies on the friction of the split ring between the bolt head and aircraft washer, I'd wonder if substituting inner- or outer-star washers might give better friction. IMHO split rings aren't that good if they can't bite into both surfaces. The friction is only at the split, not all the way around, as it would be with the star washer or belleville.

Not to be argumentative here - just thinking "out loud".

Offline

I had actually thought about doing away with the split ring, but keeping the flat washer, and buying some aircraft bolts with the "holes" in the bolt heads and then safety wiring them with .032 or .040 safety wire. I haven't seen that done before on a Healey but if it works for aircraft it should work for Healey's??Patrick,

Not necessary. Thank you for the offer.

My setup's a little different as I have a tube shock setup (homemade - similar principle to Udo's) using long bolts through the stanchions. One of these came loose for the first time in 10 years. I had been using belleville washers under the bolt heads and had had no problem but switched to grade-8 split ring washers and one of those came loose.

Since your setup relies on the friction of the split ring between the bolt head and aircraft washer, I'd wonder if substituting inner- or outer-star washers might give better friction. IMHO split rings aren't that good if they can't bite into both surfaces. The friction is only at the split, not all the way around, as it would be with the star washer or belleville.

Not to be argumentative here - just thinking "out loud".

Rob Glasgow

Jedi Knight

Offline

Do shock bolts come loose? I'd say from my 51 years of ownership, yes. Both front and rear shocks loosen over time. After I had all shocks rebuild two years ago, I used blue locktite on all bolts and they were still tight when I removed them at the beginning of the restoration this year. Several years ago, I replaced the stock cap head bolts on the rear shocks with Allen head socket head bolts. They are much easier to tighten.

Offline

Just thinking out loud here: Why not go back to the belleville washers?.... One of these came loose for the first time in 10 years. I had been using belleville washers under the bolt heads and had had no problem but switched to grade-8 split ring washers and one of those came loose.

... - just thinking "out loud".

I agree with using the blue Loctite, just make sure the threads are clean.

Bob_Spidell

Yoda

Offline

This will (re-) kindle a long-running, er, 'discussion.' In theory, a bolt in tension is held in place by steel's elasticity and the bolt being stretched. Hence, 'torque-to-yield' bolts and lack of any sort of lockwasher on critical junctions like head studs. So, a properly torqued bolt in an application where there is no 'give' besides the bolt stretch lockwashers aren't needed, and may be detrimental. Either the factory or the DPO had put split lockwashers under the bolt heads on my front shocks, and the washers had dug into the soft metal of the shock body, pretty much making them useless as far as preventing the bolt from coming undone (facing these spots is a good idea, IMO, but don't take off too much metal). I still have the original shock bolts, which I believe are the British equivalent of our Grade 8.

The reasons for using Grade 8 flatwashers is a) plain steel flatwashers are relatively soft and will compress and relieve tension on the bolt and b) plain steel washers will deform and release tension on the shock. Since a Grade 8 is larger in diameter than the bolt head, you are effectively increasing the clamping force. For (a wildly approximate) example, if the area under the bolt head is one-half inch squared, the bolt tension is 500psi, then if your Grade 8 flatwasher is one inch squared, you are effectively putting 1000 pounds of force on each corner (the area factors cancel out, if you do the math). This reduces the shock's ability to 'wiggle and squirm' its way loose. The threadlocker is just insurance, but be sure to guesstimate its effect on the torque spec (less than oil, but greater than dry).

My experience is this does not quite apply to the rear shocks, which have unsecured nuts on the backside of the mounts. I tried the Grade 8 bolt/flatwasher/threadlocker-only approach, and a shock worked loose. I still use only a Grade 8 lockwasher under the bolt head, but I use a splitwasher under the nut. I think only using threadlocker on the nut side allowed the bolt to rotate and work loose; the split lockwasher prevents that.

I don't think safety-wiring is appropriate in this case. Safety wiring only prevents a bolt or nut from coming loose entirely, which is why it's widely used in aircraft where the results of things coming apart often ain't pretty. The safety wire itself is not strong enough to hold the torque on the bolt/nut, and there's still some give in the wire even when properly twisted (I believe the 'spec' is 9-12 twists/inch). Also, using safety wiring properly is almost a course in itself for aircraft mechanics--you always have to wire in the direction that keeps tightening tension on the bolt/nut, and the wire must be properly secured to an anchor, or another bolt/nut--and requires a jig to drill proper holes in the bolt heads and/or nut. One good thing: safety wire-twisting pliers used to be very expensive, but you can get decent ones at Harbor Freight at a fraction, and they work well enough.

The reasons for using Grade 8 flatwashers is a) plain steel flatwashers are relatively soft and will compress and relieve tension on the bolt and b) plain steel washers will deform and release tension on the shock. Since a Grade 8 is larger in diameter than the bolt head, you are effectively increasing the clamping force. For (a wildly approximate) example, if the area under the bolt head is one-half inch squared, the bolt tension is 500psi, then if your Grade 8 flatwasher is one inch squared, you are effectively putting 1000 pounds of force on each corner (the area factors cancel out, if you do the math). This reduces the shock's ability to 'wiggle and squirm' its way loose. The threadlocker is just insurance, but be sure to guesstimate its effect on the torque spec (less than oil, but greater than dry).

My experience is this does not quite apply to the rear shocks, which have unsecured nuts on the backside of the mounts. I tried the Grade 8 bolt/flatwasher/threadlocker-only approach, and a shock worked loose. I still use only a Grade 8 lockwasher under the bolt head, but I use a splitwasher under the nut. I think only using threadlocker on the nut side allowed the bolt to rotate and work loose; the split lockwasher prevents that.

I don't think safety-wiring is appropriate in this case. Safety wiring only prevents a bolt or nut from coming loose entirely, which is why it's widely used in aircraft where the results of things coming apart often ain't pretty. The safety wire itself is not strong enough to hold the torque on the bolt/nut, and there's still some give in the wire even when properly twisted (I believe the 'spec' is 9-12 twists/inch). Also, using safety wiring properly is almost a course in itself for aircraft mechanics--you always have to wire in the direction that keeps tightening tension on the bolt/nut, and the wire must be properly secured to an anchor, or another bolt/nut--and requires a jig to drill proper holes in the bolt heads and/or nut. One good thing: safety wire-twisting pliers used to be very expensive, but you can get decent ones at Harbor Freight at a fraction, and they work well enough.

Offline

Some years ago when I put new shocks on I decided to use locktight. When I recently restored the car I did not take the front suspension apart because I new it was good. And the shocks "appear" as tight as you would want them. I say appeared because even when I first applied the locktight I knew that I would never retorque the bolts because in doing so I figured it would break the locktight loose. So I was hesitant to use the locktight but I did. So after all this time the front end is tight and smooth and I'm sure I'll know it when something loosens up. I suppose if I was concerned about it I could pull each bolt clean them and reapply the locktight and retorque. Dave.

Bob_Spidell

Yoda

Offline

That's interesting - suspect there might me more to it. If you put a bolt through a steel cone with 5x the area of your bolt head, would you have 5x the pressure. Doesn't feel right, but have no idea where to find a citation on it.

Agreed. I think I confused tensile strength with clamping load: https://www.spaenaur.com/pdf/sectionD/D48.pdf I was confused clamp force with hydraulics where, of course, pressure can be amplified by varying surface areas.

At any rate, Grade 8 washers aren't that much more expensive, and if your purpose is to spread a load they're the way to go (why even stock mild steel washers?).

Bob_Spidell

Yoda

Offline

Note blue Locktite now comes as a tape (sort of like teflon tape). Expensive as all get out, but if you don't like most of it dripping off onto your shoes ...