I have to pull the gearbox to change out the clutch and get the flywheel resurfaced. I was wondering about lightening the stock flywheel.I don't want to go to the expense of installing an aluminum flywheel and I do know a machinist that would do it for a reasonable price. I was wondering if anyone had any information as to where to drill the flywheel and how much to take off etc. How would a lightened flywheel affect performance and what would I have to adjust in terms of retuning the engine?My 3 has a rebuilt motor, Petronix,a header,mild street cam,stock SU's,4A intake. Is doing this worth the effort or am I wasting my time for a small gain in performance?

-

Hi Guest!

Hi Guest!

You can help ensure that British Car Forum (BCF) continues to provide a great place to engage in the British car hobby! If you find BCF a beneficial community, please consider supporting our efforts with a subscription.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TR2/3/3A Lightening a stock TR3A flywheel.....

- Thread starter karls59tr

- Start date

tinman58

Jedi Knight

Offline

Karl

I just had my flywheel lightened by 7 lbs. That was the most the machinist thought was safe. My engine sounds similar to yours except I have the Moss Supercharger. The extra zip is worth the expense. The machinist had to enlarge the hole at the center of the flywheel to mount the flywheel on the lathe. I gave him the pressure plate and let him do the layout. For the amount of cost ($250) I think it is a lot of fun for the buck.

I just had my flywheel lightened by 7 lbs. That was the most the machinist thought was safe. My engine sounds similar to yours except I have the Moss Supercharger. The extra zip is worth the expense. The machinist had to enlarge the hole at the center of the flywheel to mount the flywheel on the lathe. I gave him the pressure plate and let him do the layout. For the amount of cost ($250) I think it is a lot of fun for the buck.

TR3driver

Great Pumpkin - R.I.P

Offline

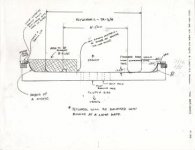

Here's a photo that might help

That's a billet steel flywheel (from ARE), rather than a cut-down original, but it shows the areas that need to be left and the ones that can be removed.

I have a Fidanza aluminum flywheel on my TR3, which at 10 pounds is much lighter than you can take the stock cast iron wheel (without risk of having your feet amputated anyway). I didn't make any special changes to the motor, but note that you want good low end torque or the car will be harder to launch. The engine in my TR3A didn't pull so well at low rpm, and it was a bit of a learning experience not to kill the engine when driving casually. The motor in my current TR3 pulls better below 1500 rpm, and I've still killed it once or twice.

I see the Fidanzas have gone up since I bought mine some 20 years ago, but still only $310 at Amazon. For $60 more, I'd still go that way. But note that the Fidanza comes drilled only for the TR4A clutch. You'll need to either use a TR4A pressure plate, TOB & carrier to match it, or have it redrilled for the earlier clutch. I went the TR4A route, as it is also lighter than the stock TR3-4 clutch.

That's a billet steel flywheel (from ARE), rather than a cut-down original, but it shows the areas that need to be left and the ones that can be removed.

I have a Fidanza aluminum flywheel on my TR3, which at 10 pounds is much lighter than you can take the stock cast iron wheel (without risk of having your feet amputated anyway). I didn't make any special changes to the motor, but note that you want good low end torque or the car will be harder to launch. The engine in my TR3A didn't pull so well at low rpm, and it was a bit of a learning experience not to kill the engine when driving casually. The motor in my current TR3 pulls better below 1500 rpm, and I've still killed it once or twice.

I see the Fidanzas have gone up since I bought mine some 20 years ago, but still only $310 at Amazon. For $60 more, I'd still go that way. But note that the Fidanza comes drilled only for the TR4A clutch. You'll need to either use a TR4A pressure plate, TOB & carrier to match it, or have it redrilled for the earlier clutch. I went the TR4A route, as it is also lighter than the stock TR3-4 clutch.

TR3driver

Great Pumpkin - R.I.P

Offline

I was just looking for that, with no luck. If you happen to remember which one, please let us/me know.I believe there are instructions as well as a drawing in one of Kas Kastners Competition books.

Bremer

Jedi Hopeful

Offline

Info is in this thread:

https://www.britishcarforum.com/bcf/showthread.php?67045-TR3-Flywheel-Weight

https://www.britishcarforum.com/bcf/showthread.php?67045-TR3-Flywheel-Weight

TR3driver

Great Pumpkin - R.I.P

Offline

Ah, OK, I found that passage in the 2003 version "Triumph Preparation Handbook", page 121. No diagram though, and the photo shows a lot of work that wasn't done on a lathe. The original factory TR3 & TR4 "Competition Preparation" manuals (which were also written by Kas Kastner) just say to use aluminum.

Where did your machinist remove the material from the flywheel? One of the replies to my question led to what Kastner said on the topic..."most weight is taken from the outside and on the cylinder block side"....not sure what is meant by the outside?Karl

I just had my flywheel lightened by 7 lbs. That was the most the machinist thought was safe. My engine sounds similar to yours except I have the Moss Supercharger. The extra zip is worth the expense. The machinist had to enlarge the hole at the center of the flywheel to mount the flywheel on the lathe. I gave him the pressure plate and let him do the layout. For the amount of cost ($250) I think it is a lot of fun for the buck.

TR4nut

Yoda

Offline

Joe Alexander did mine a few years ago, not sure if he still does it. I think there is a drawing floating around that possibly Jack Drews made showing where the material is removed on a TR3/4 flywheel. Can't find it right now - but Dave Vizard's tuning book has some pics:

https://www.scribd.com/doc/12986341/Tuning-Standard-Triumphs-Vizard

https://www.scribd.com/doc/12986341/Tuning-Standard-Triumphs-Vizard

tomshobby

Yoda

Offline

Here's a photo that might help

That's a billet steel flywheel (from ARE), rather than a cut-down original, but it shows the areas that need to be left and the ones that can be removed.

I have a Fidanza aluminum flywheel on my TR3, which at 10 pounds is much lighter than you can take the stock cast iron wheel (without risk of having your feet amputated anyway). I didn't make any special changes to the motor, but note that you want good low end torque or the car will be harder to launch. The engine in my TR3A didn't pull so well at low rpm, and it was a bit of a learning experience not to kill the engine when driving casually. The motor in my current TR3 pulls better below 1500 rpm, and I've still killed it once or twice.

I see the Fidanzas have gone up since I bought mine some 20 years ago, but still only $310 at Amazon. For $60 more, I'd still go that way. But note that the Fidanza comes drilled only for the TR4A clutch. You'll need to either use a TR4A pressure plate, TOB & carrier to match it, or have it redrilled for the earlier clutch. I went the TR4A route, as it is also lighter than the stock TR3-4 clutch.

I have had a Fidanza on my TR6 for several years. I thought it was closer to 9 lbs but may be wrong. It is great at low end and acceleration and impressive in the mountains (in the East or West) on up hill grades even pulling a trailer. I agree with Randall's comments. Although I haven't had problems stalling my 6.

TR3driver

Great Pumpkin - R.I.P

Offline

According to the Fidanza application chart https://www.fidanza.com/Files/catalog.pdf , the later TR6 version is 11.65 pounds. Dunno why, though, a 6 pot should be able to get by with less than a 4.

The original tr2 flywheel tipped in at 23 lbs, the tr3 at 32 lbs .If you can lose

9 or 10 lbs it is nice.The tr2 unit had a lot of metal off the engine side and was a little

weaker.I like the off the perimeter approach as in the picture. It saves rotational inertia

which is the real issue.When you do this , it should be balanced to the crankshaft it will

be married to.....

MD(mad dog)

9 or 10 lbs it is nice.The tr2 unit had a lot of metal off the engine side and was a little

weaker.I like the off the perimeter approach as in the picture. It saves rotational inertia

which is the real issue.When you do this , it should be balanced to the crankshaft it will

be married to.....

MD(mad dog)