AUSMHLY

Yoda

Offline

I'm wondering if I can get that last bit of flash bleed-over from my dash directional to cancel out.

I've replaced the two incandescent 2.2 watt bulbs with two led bulbs.

I've replaced the stock flasher unit with an electronic unit. That unit has eliminated almost all of flash bleed-over.

I was reading that installing a load resistor solves this problem.

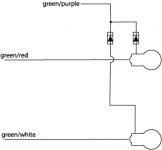

I've found one that seems like it will work. Directions say, connect one wire to ground and the other wire to the turn/brake wire. I would like to connect it to the directional dash bulb, rather than the actual turn/brake bulb.

I don't see what would be a ground wire.

What two wires would I splice into?

I've replaced the two incandescent 2.2 watt bulbs with two led bulbs.

I've replaced the stock flasher unit with an electronic unit. That unit has eliminated almost all of flash bleed-over.

I was reading that installing a load resistor solves this problem.

I've found one that seems like it will work. Directions say, connect one wire to ground and the other wire to the turn/brake wire. I would like to connect it to the directional dash bulb, rather than the actual turn/brake bulb.

I don't see what would be a ground wire.

What two wires would I splice into?

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>