John Loftus

Darth Vader

Offline

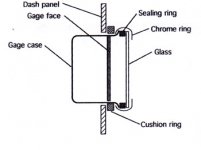

I need to replace the rubber sealing rings for all the gauges. When I removed the chrome trim ring for the tach and speedo there were remnants (crumbly, black, hard) of something that went between the glass and trim ring. In the catalogs they show a sealing ring but it looks like this goes between the instrument panel and gauge. Does anyone know exactly what is needed between:

1. the instrument panel and gauge

2. the glass and instrument

3. the glass and trim ring

Thanks,

John

BJ7

1. the instrument panel and gauge

2. the glass and instrument

3. the glass and trim ring

Thanks,

John

BJ7

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>