CJD

Yoda

Offline

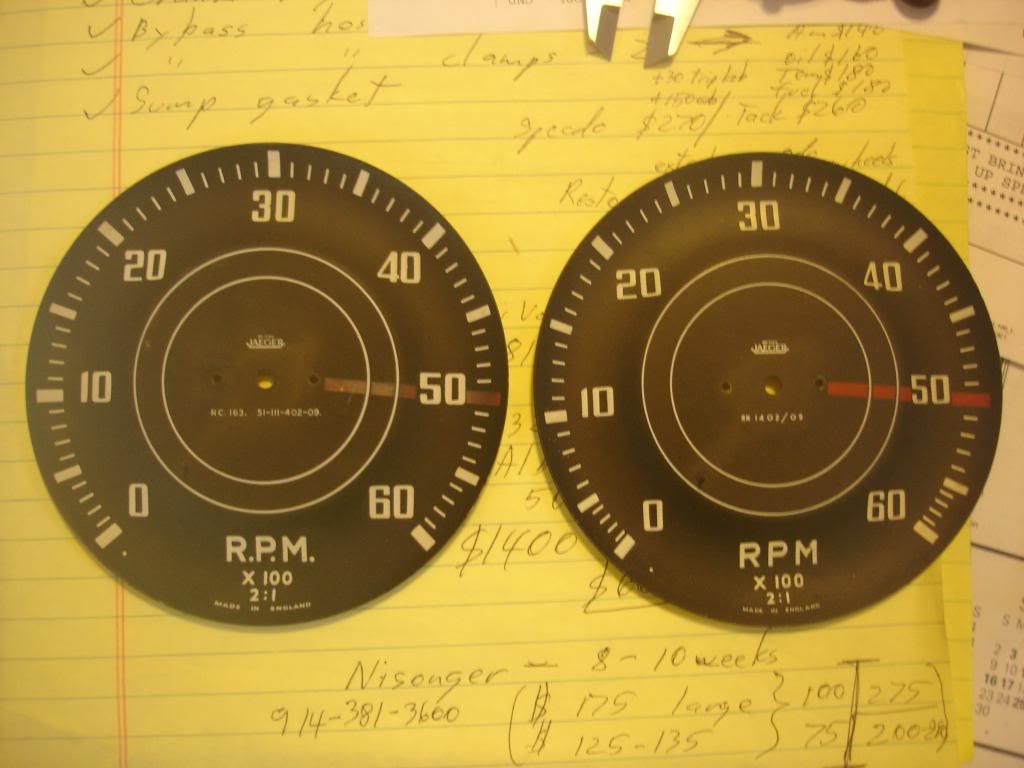

For the last restoration I was able to avoid this issue, but not so this time. I am not satisfied with the condition of my instrument faces. The black has differring shades, and the red rpm limit line is tan from sun exposure. The parts car has similar issues, but chiefly there are differences between the markings on a TR2 and a TR3 markings. So here goes:

1) Does anybody know of a source for new or reconditioned instrument faces? I know Nisonger "says" they have them, but will not sell without using their gage rebuild service...like $2 grand. I farm nothing out but machine work, so I cannot bring myself to farm this out.

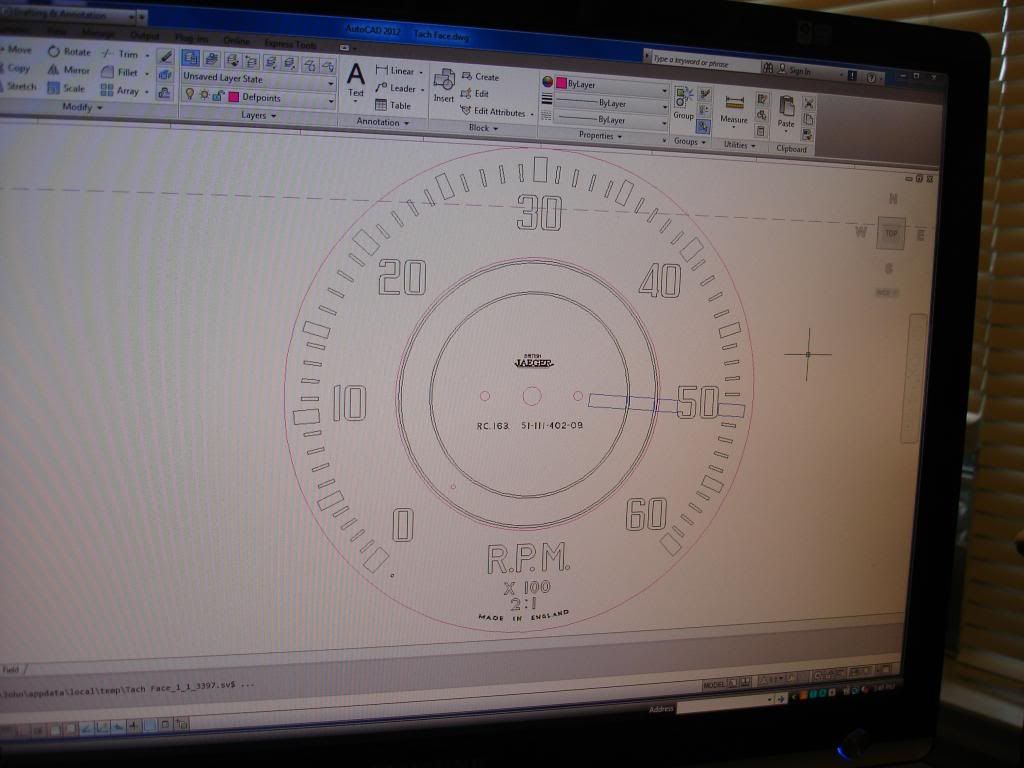

2) Does anyone know how the original faces were painted? It is obvious the black went on first. The white looks like silk screen...however I have never seen a silk screen that works on a curved surface. I have a laser cutter, so I can cut silk screen or vinyl maskings...but some of the detail is even too small for any silk screen or masking I have ever seen. Their technique in those days baffles me, so anybody have insight how it was done?

3) Anybody have an idea of what type paint these instrument faces were painted with? Black is easy, since I can etch the surface and bond it permanently. The white has to be very high density to cover over black with, presumably, one pass. The red on the tack looks substandard on the originals, so I'm not worried about that.

Learning to paint instrument faces has been a goal of mine since my first restoration. With the laser I can cut masks accurate within .005", which is the width of the laser beam. But cutting any mask on a curved surface is shady at best. I can cut the mask from vinyl, and then stretch over the curves, but that will result in a distortion of the markings. They had to use a trick. There has to be a way to duplicate it...and once we do, instrument restoration will be a cinch!

So, please, I welcome any ideas...!

1) Does anybody know of a source for new or reconditioned instrument faces? I know Nisonger "says" they have them, but will not sell without using their gage rebuild service...like $2 grand. I farm nothing out but machine work, so I cannot bring myself to farm this out.

2) Does anyone know how the original faces were painted? It is obvious the black went on first. The white looks like silk screen...however I have never seen a silk screen that works on a curved surface. I have a laser cutter, so I can cut silk screen or vinyl maskings...but some of the detail is even too small for any silk screen or masking I have ever seen. Their technique in those days baffles me, so anybody have insight how it was done?

3) Anybody have an idea of what type paint these instrument faces were painted with? Black is easy, since I can etch the surface and bond it permanently. The white has to be very high density to cover over black with, presumably, one pass. The red on the tack looks substandard on the originals, so I'm not worried about that.

Learning to paint instrument faces has been a goal of mine since my first restoration. With the laser I can cut masks accurate within .005", which is the width of the laser beam. But cutting any mask on a curved surface is shady at best. I can cut the mask from vinyl, and then stretch over the curves, but that will result in a distortion of the markings. They had to use a trick. There has to be a way to duplicate it...and once we do, instrument restoration will be a cinch!

So, please, I welcome any ideas...!

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>