-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TR2/3/3A Installing Brake Caliper pistons into the bore?

- Thread starter karls59tr

- Start date

I had more trouble getting one of the pistons out. One side came apart no problem with a careful puff of air in the brake line port. The other side one piston came out but the other one was stuck.

I ended up attaching a grease fitting to the brake line port, blanking off the other side and pumping grease in till it moved. Did not think the grease gun was going to get it done at first. At last it moved. It seems there was a blockage in the passageway in the caliper which took some time to get clear.

That may have been why the brakes were sticking on that side.

David

I ended up attaching a grease fitting to the brake line port, blanking off the other side and pumping grease in till it moved. Did not think the grease gun was going to get it done at first. At last it moved. It seems there was a blockage in the passageway in the caliper which took some time to get clear.

That may have been why the brakes were sticking on that side.

David

Sounds like plan. How did you get the grease out of the caliper?I had more trouble getting one of the pistons out. One side came apart no problem with a careful puff of air in the brake line port. The other side one piston came out but the other one was stuck.

I ended up attaching a grease fitting to the brake line port, blanking off the other side and pumping grease in till it moved. Did not think the grease gun was going to get it done at first. At last it moved. It seems there was a blockage in the passageway in the caliper which took some time to get clear.

That may have been why the brakes were sticking on that side.

David

When I do brakes I always coat any exterior rubber seals with silicone grease, especially where they contacts the caliper and the piston. This helps prevent any water from working its way under the boot and starting the corrosion process. Brake fluid in these areas will only attract moisture. Been working well for me for many years

Would the silicone grease not get onto the rotor?When I do brakes I always coat any exterior rubber seals with silicone grease, especially where they contacts the caliper and the piston. This helps prevent any water from working its way under the boot and starting the corrosion process. Brake fluid in these areas will only attract moisture. Been working well for me for many years

I see your point. I looked at that rubber steel joint on the piston that you mentioned and did see rust build up there. I will be ordering new pistons soon and will make sure to lubricate that area. I see that Moss does not have the standard rubber seal kit for the pistons. I found an unused original Girling set in a parts bin I had. The TRW outer seal that Moss shows look quite different than stock ones? Did you use those on your last rebuild?No reason it would, I'm not putting a lot of grease on the seals just a skim coat and working it down into the rubber/steel joint. No reason it should migrate all the way to the rotors.

Did you use the "TRW seal kit" from Moss on any of your rebuilds and did you notice any difference between that kit and the original "Girling seal kit" ?Ummmm, haven't finished my TR-3 calipers but I've done this on eight vehicles in the last 10 yrs.

charleyf

Luke Skywalker

Offline

If you are using a vise to press in the pistons in place you must be separating the two halves of the caliper. This operation does not require you to do that. I have done quite a few now and have never separated the calipers.

Also I use a 1" by 3" by 12" board to push the pistons into the calipers. Very little force is needed. The key is getting them in straight.

Charley

Also I use a 1" by 3" by 12" board to push the pistons into the calipers. Very little force is needed. The key is getting them in straight.

Charley

Thanks. That's why I did not understand Sarastros post. Normally TR3 calipers are never separated as there is no known torque value to reinstall the halves.If you are using a vise to press in the pistons in place you must be separating the two halves of the caliper. This operation does not require you to do that. I have done quite a few now and have never separated the calipers.

Also I use a 1" by 3" by 12" board to push the pistons into the calipers. Very little force is needed. The key is getting them in straight.

Charley

Offline

Thanks. That's why I did not understand Sarastros post. Normally TR3 calipers are never separated as there is no known torque value to reinstall the halves.

i did this on my sp250 the brakes are the same and the workshop manual gives figures.

but there is a small rubber "o" ring that seals the 2 faces that you would need to find and ensure they are brake fluid compatible

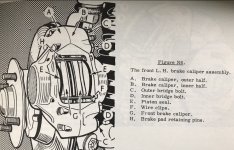

see the attached as there are differing numbers for the inner and outer bolts and it shows which is which.

H

Attachments

Were you able to find a torque value for those bolt? What torque did you go with? I've always heard that it is not necessary to or advisable to separate the caliper halves but I see how it would be easier to compress the pistons. Some say the new pistons go in quite easily?i did this on my sp250 the brakes are the same and the workshop manual gives figures.

but there is a small rubber "o" ring that seals the 2 faces that you would need to find and ensure they are brake fluid compatible

see the attached as there are differing numbers for the inner and outer bolts and it shows which is which.

H

Offline

All the info is in the pictures I posted of the Daimler workshop manualWere you able to find a torque value for those bolt? What torque did you go with? I've always heard that it is not necessary to or advisable to separate the caliper halves but I see how it would be easier to compress the pistons. Some say the new pistons go in quite easily?

Offline

I would add that the sp250 calipers are the same type as the later TR4 etc as they have the pad retaining pins. Unlike the earlier spring metal plate of the 3a.

But having done the sp250 brakes there is nothing scary in splitting the caliper (if you really have to)

But having done the sp250 brakes there is nothing scary in splitting the caliper (if you really have to)