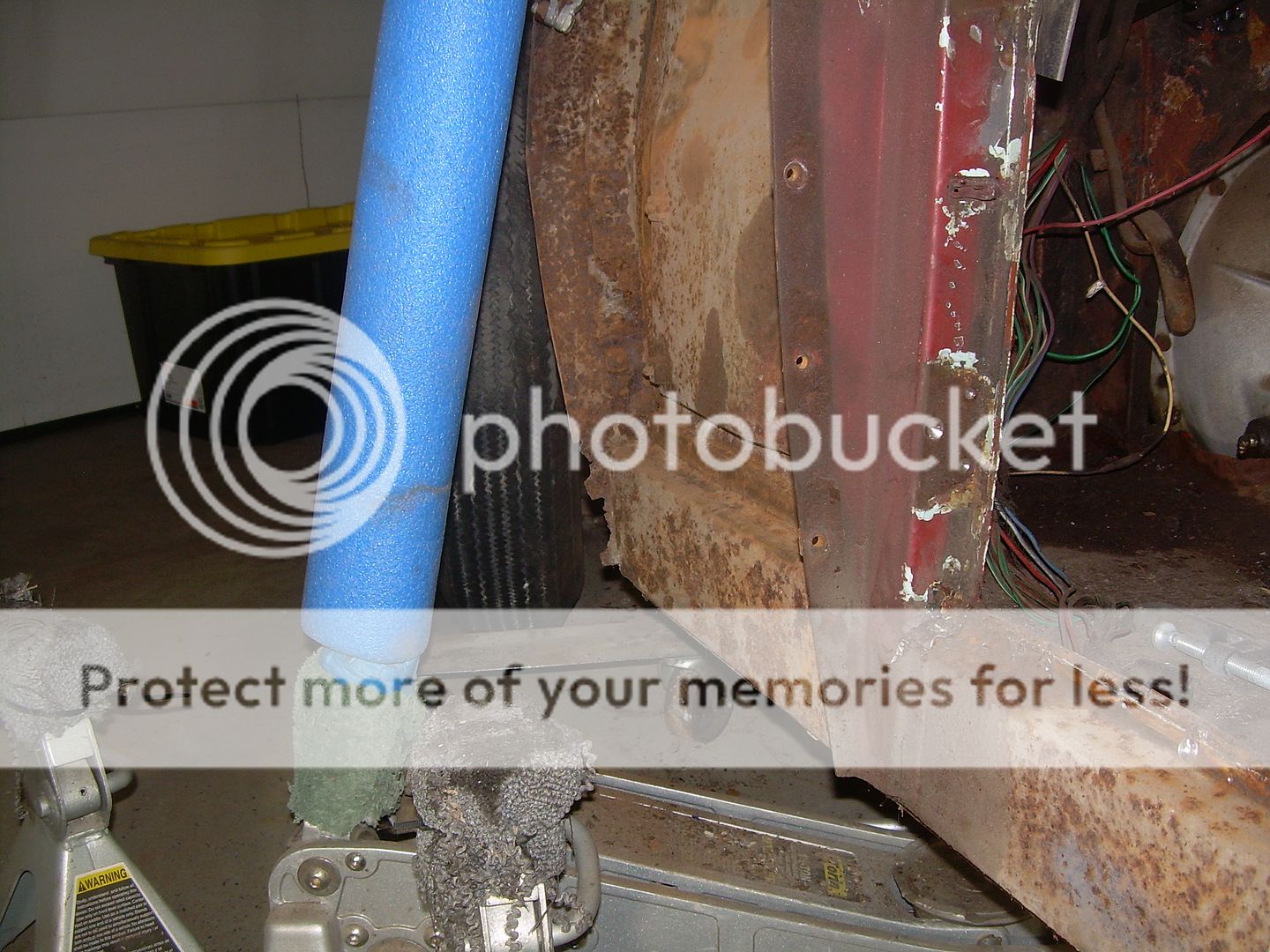

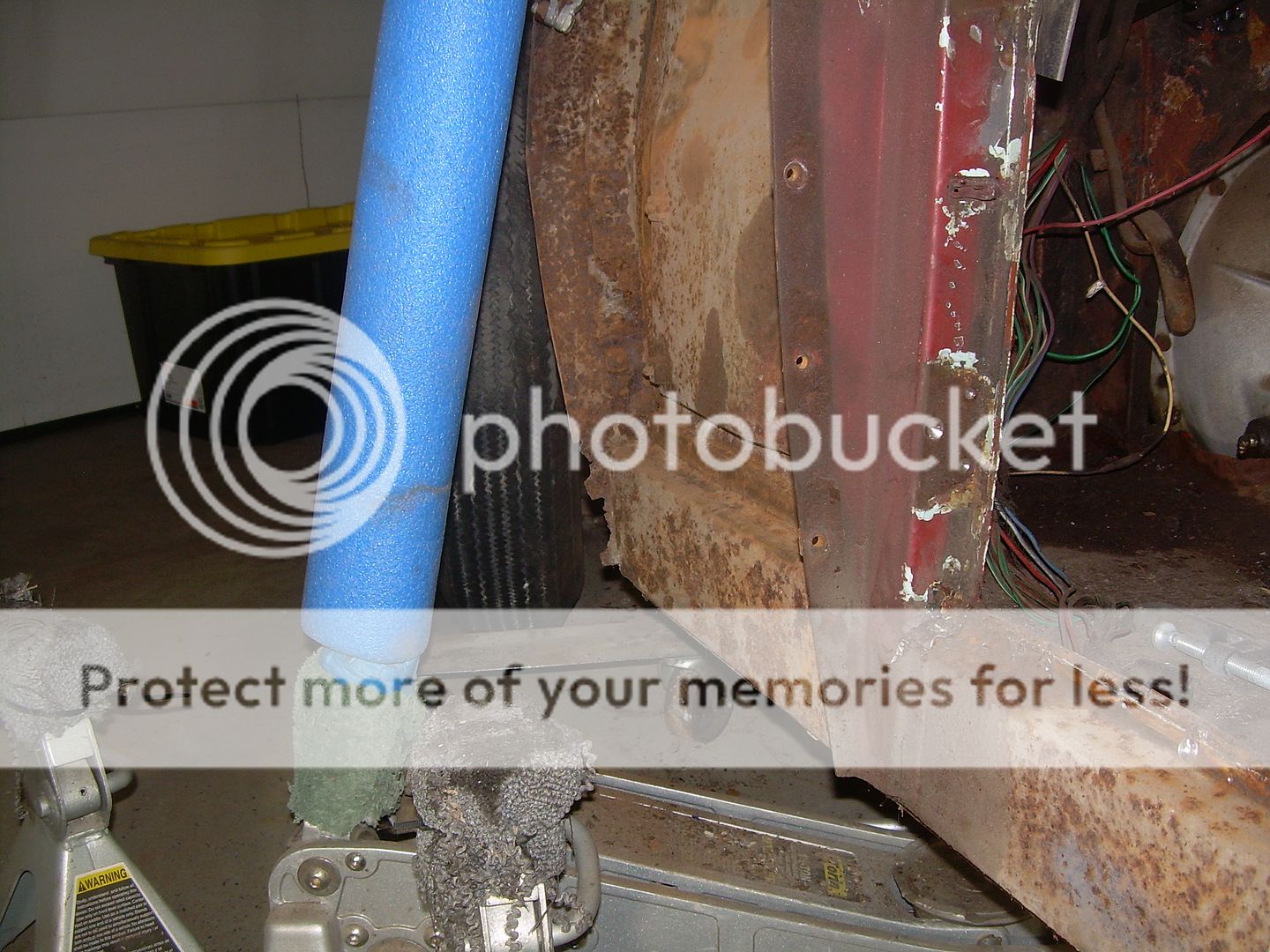

I could use some advice on how to proceed with the replacement of The inner sill and the floors along with the rusted out parts that can be seen in my pictures. I plan to make repair panels to patch the rotted areas.From what I have read here the A post is spot welded along the outside onto the Inner sill.

Where are the spot welds that attach the B post to the sill?

Do I need to remove the rear quarter panel?

I'm thinking that my plan of attack should be to remove all the rusted out Sill along with the outside edge of the floor which should allow me to fit the new sill in place and get it bolted down. Once I have that in place I would plan to remove the rest of the floor and position that. Finally I would make the patch panels and weld them in there correct position relative to the new floor and sill.

I would appreciate some advice as to if I'm heading in the right direction with my plan.

Thanks Jeff

Where are the spot welds that attach the B post to the sill?

Do I need to remove the rear quarter panel?

I'm thinking that my plan of attack should be to remove all the rusted out Sill along with the outside edge of the floor which should allow me to fit the new sill in place and get it bolted down. Once I have that in place I would plan to remove the rest of the floor and position that. Finally I would make the patch panels and weld them in there correct position relative to the new floor and sill.

I would appreciate some advice as to if I'm heading in the right direction with my plan.

Thanks Jeff

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>