.

Here's an article by Curt Arndt, chairman of the concours committee, that I published several years ago:

Refinishing "Bakelite"

Curt Arndt

Carlsbad, California

The original "trafficator" – the round, black crown in the center of the steering wheel found in all big Healeys – sometimes needs a little rejuvenation to keep it looking new. I've restored a dozen or more of these items over the years and I learned from an elderly gentleman who restored old radios (the knobs and assorted pieces on many old radios were made of the same material) how to bring back the “Bakelite” without removing its unique look and patina.

Bakelite is one of the first plastics (Dr. Leo Baekeland, 1908, father of the plastics industry) and is made from a formaldehyde formula and some sort of filler, which was in many cases wood (sawdust). It tends to dry out over the years and needs to be re-moisturized to keep it from becoming more brittle than it already is, and you will see that there are a number of ways to accomplish this.

Usually I clean the pieces first with warm soapy water and a toothbrush to get the years of dirt, grime, grease and miscellaneous crud off. If the surface is rough at all, which it will be if it has spent any amount of time exposed to the elements, the surface will need to be smoothed out. I will usually start with #0000 steel wool (equal to 600-grit sandpaper) and then work through 1000- then 1500-grit wet sandpaper. I then polish the piece carefully on a special soft-string wheel with plastic polish on my buffer. WARNING: If you use a buffer, be extremely careful to hold onto the piece tightly because if you lose your grip and the piece flies out of your hand and hits the floor, it's history!

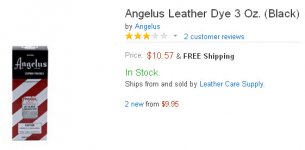

You may now notice that the piece has a speckled brown/golden tinge to it, and no, I'm not talking about brown Bakelite, that's different. What you see are the filler specks (sawdust pieces) that have bleached out over the years from exposure. Depending on the degree of discoloration, the piece can be dyed with black India ink.

The next step is to re-moisturize the piece. I normally use plain black Kiwi brand shoe polish and then hand buff until there is no residue left. Other folks that I know have used "Neatsfoot" oil, mink oil or clear mineral oil, none of which I have tried but from seeing some of their finished work, it looks very good. Finally, I will apply a good carnuba wax to finish the piece. The results can be spectacular and far superior to just painting the piece, which may be your only option if the piece is broken and you have to repair it with filler.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<