I agree wit Geoffrey Healey, Engine cooling conclusions and to explain my project beginning and conclusion

for avoid overheating problems at my AH in the Italian Summer sunny days

The original FAN was completely inadeguate and also dangerous to the air flush circulation

the first step to avoid HEAT was the acquisition of TEXAS plastic FAN , improved flush air, are incomparable to the oldest

I considered the internal front body of the AH , and the air flush at speed and a moderate speed

at stationary, or moderate speed, radiator flush friction are nearest to a brick wall with oldest fan -with Texas fan are again insufficient to cooling the engine completely- consideration are that this are the more recurring situation on the city traffic, the probability of engine cooling turn to critical in this situation are nearest to 80%

at medium and high speed the flush through the radiator are better and cooling is adeguate to the engine heat

BUT it can be increased

1) adding more surface to the radiator OR

better installing the OIL Radiator (remember that air cooled, and water engines are il large part cooled by the oil (in my 911 13 Liters of oil in circulation ) NOTE: this require ALSO a THERMOSTATIC valve for controlled temperature

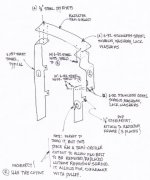

2) a Front ducting are one of the better step to increase the air pressure and efficiency of the FAN

3) FAN Ducting increase the efficiency of fan, and flush in the engine bay

4) one Electric fan pushing air from front radiator to the rear engine fan -can help in extreme heat condition slow traffic or queue better with a Thermostatic control

https://photos.app.goo.gl/mUwV8r6hsoUVuRAA3

https://photos.app.goo.gl/ce5raV24VTw0w3oO2 NOTE the Duct also on oil radiator -for air flush optim.

5) No forget to control the water gauge reliability controlling it by a digital thermometer

https://photos.app.goo.gl/j0p7Tls9Yxc5TW2h2

Applying all to your AH and never you have overheat problems in summer or Stelvio high drop climb road, or evacuation queue

(Actually I haven't applied to my AH the 3 step- waiting to find a stainless ribbon -to make a compete circumference duct around the fan)

Consider also where the car is destined to circulation in Alaska have others problems than the cars in circulation in Texas or Italy

On my MG TD and TC shifting from the original Steel Fan to a six or seven blade Plastic Fan (MG B) solved permanently the overheat problems

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.