Bruce Edge

Freshman Member

Offline

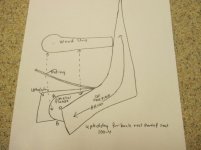

I have a new leather seat kit from Moss. I have used their upholstery kits in the past and have been able to install them without having to take to a professional upholstery shop. Not so with these 100-4 seats. I do not have any old patterns to go by. I cannot figure how the material is attached around the flange section of back part of the seat. This is the section that the hinge bolts go through to attach to the bottom seat pan. So I took it to a 40+year experienced upholster and he is not sure how to do it either. He has done later model Healeys where that section of the cover is in two pieces (not all one piece like this one). I know this is a lot to ask, but if someone could please take some detail digital pictures of that area of the seat particularly showing how the piping runs under the bottom and ends up at the back of the seat. I know this rambling is very confusing, I just hope someone has gone through this and understands what I'm asking.

Any help much appreciated,

Bruce

Any help much appreciated,

Bruce

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>