-

Hey Guest!

Hey Guest!

British Car Forum has been supporting enthusiasts for over 25 years by providing a great place to share our love for British cars. You can support our efforts by upgrading your membership for less than the dues of most car clubs. There are some perks with a member upgrade!**Upgrade Now**

(PS: Upgraded members don't see this banner, nor will you see the Google ads that appear on the site.)

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HD8 Carbs Removal

- Thread starter Goldie

- Start date

GregW

Yoda

Offline

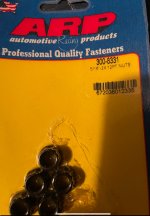

Summit racing carries ARP nuts.

12 point ARP

12 point ARP

Offline

Summit racing carries ARP nuts.

12 point ARP

Attachments

Oh man, I just started this same carb removal and ran into the same problem, thus consulted this forum. I too was hoping to read about the 'miracle cure'. I'll try your suggestions - shorter wrenches, grinding down the outer edges, bending the handle, etc. If the "OD" of the box end of a wrench is ground down, will that enable it to fit between the nut and the carb body? (Is that what bdcvg is suggesting?) And the 12 pt / jet / ARP nuts sound like the way to go for reassembly - looks like a special wrench is needed for those 12 pt nuts because they don't have flat faces - more like a star nut?

Offline

Nothing special other than a 1/4” ratchet, elbow and the correct 12 pt socket size. I think I used a short 3” extension too.Oh man, I just started this same carb removal and ran into the same problem, thus consulted this forum. I too was hoping to read about the 'miracle cure'. I'll try your suggestions - shorter wrenches, grinding down the outer edges, bending the handle, etc. If the "OD" of the box end of a wrench is ground down, will that enable it to fit between the nut and the carb body? (Is that what bdcvg is suggesting?) And the 12 pt / jet / ARP nuts sound like the way to go for reassembly - looks like a special wrench is needed for those 12 pt nuts because they don't have flat faces - more like a star nut?

I bought half moon wrenches and off-set wrenches to try and get a better angle. Neither worked. I had to use my thin 1/2 inch wrench that is about 4 inches long. It has a straight open end and a 90 degree open end. I managed to get the nut just to turn ever so slightly and then worked it a little turn at a time. It was slow and tedious and a royal pain. I don't think there is a magic bullet, just a bad design for maintenance. A little trouble putting them back on but not as difficult a taking the bottom inside nuts off. I probably dropped the washers and nuts several times before getting them on those studs. I had placed towels and paper towels under the carbs so I could find the parts when I dropped them. My magnet got a good workout as well. Good luck. It is aggravating.

AUSMHLY

Yoda

Offline

Did you try the stubby wrench I suggested from Harbor Freight? Just the right size, and I tried a lot of wrenches.

I put a little dum dum between the washer and lock nut to keep them together for installation.

We all go through the misery of getting those two washers/lock washers/nuts off/on.

Congrats on your success.

I put a little dum dum between the washer and lock nut to keep them together for installation.

We all go through the misery of getting those two washers/lock washers/nuts off/on.

Congrats on your success.

Offline

Thanks. I was thinking that a socket and ratchet wouldn't fit in the space, but that will be great if it does.

I use this setup for the bottom carb bolts on my BJ8 plus the appropriate size socket. The HANDEE CLAMP comes in real handy holding nuts in position too.

Attachments

Bob_Spidell

Yoda

Offline

When I am forced to do this job I just keep repeating to myself: "At least it isn't the front suspension bushings."

Just got the carbs out. Not terribly bad, the un-modified stubby was all I needed. I must have skinny contortionist arms. Thanks all for your advice. I'm sure I'll be back with more questions as I start the carb rebuild process. In fact - 1st question - how do I assess whether I need the more expensive rebuild kit with the new throttle shafts? And/or oversize shaft (for which it looks like a $370 reamer is needed)?

roscoe

Jedi Knight

Offline

If/when you get to that stage it might be worth finding a machine shop nearby who can ream simple things like that to size. Or send them out to a specialty shop if the price for reaming is right. Also, adjustable reamers aren't that expensive, they just take some time and trial and error testing to set them up. If you are careful you can get good results with them.

hueyhoolihan

Freshman Member

Offline

Now struggling with getting the last 2 interior nuts on the carb to manifold bolts. I have finally learned after many, many years of dropping parts, bits, and tools into the frame, I now put a cloth towel and paper towels to block off the abyss that seems to exist in the engine bay. I am going to try to find those nuts on the internet.

if and when i drop anything into the engine compartment of one of my sports cars that's smaller than, let's say, a sparkplug socket, i've got about a 50/50 chance of ever seeing it again. you'd think i'd have learned how to avoid that happening (see quote) by now.