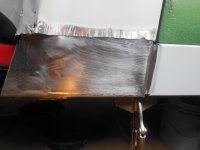

I made a small piece to use on the bottom quarter panel, but I am afraid to try and weld the piece in place along the front. I can weld the bottom and both sides, but where the 2 piece overlap in the front, I know/kinda that I will burn through sorta. I am thinking about gluing it with panel adhesive. thoughts and ideas please

-

Hey Guest!

Hey Guest!

British Car Forum has been supporting enthusiasts for over 25 years by providing a great place to share our love for British cars. You can support our efforts by upgrading your membership for less than the dues of most car clubs. There are some perks with a member upgrade!**Upgrade Now**

(PS: Upgraded members don't see this banner, nor will you see the Google ads that appear on the site.)

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TR2/3/3A gluing it with panel adhesive

- Thread starter sp53

- Start date

Offline

Moisture reactive polyurethane (Gorilla Glue) is good for body panels if there is enough contact surface.

Bob

Bob

Alfred E. Neuman

Jedi Trainee

Offline

If you have a good automotive paint and body supply shop near you, pick up 3M Panel Bonding Adhesive. It's a 2 part epoxy that you run it through a gun with a mixing tip. If you do your panel prep per their intructions, when it sets up it's not ever coming back apart. I've seen demonstrations where the metal tears before the panel bond lets go.

3M Panel Bond

3M Panel Bond

Thanks you guys I will look into the glue stuff more. Hey Bob there is about a ½ inch overlap on the metals. The overlap and how to get in and get out without making only a mess, I see as a problem. It seems I could smear the adhesive on both sides---- slide the piece into place--- put a screw in it---- and wait then weld sides and bottom. I am developing the plan on the fly, so that should work right you all???

steve

steve

Alfred E. Neuman

Jedi Trainee

Offline

I might worry about welding on a small panel that I'd bonded into a car. I'm not sure how that epoxy would respond to the heat.

Offline

You are NOT doing this right.The repair panel must be shaped a bit at the bottom.Also there is a cage nut

that must be installed prior to welding the panel on. There is some access to the inside, so any warping

can be dealt with later. Never weld close to a bonded joint. DO NOT become your avatar in real life.

Mad dog

that must be installed prior to welding the panel on. There is some access to the inside, so any warping

can be dealt with later. Never weld close to a bonded joint. DO NOT become your avatar in real life.

Mad dog

Alfred E. Neuman

Jedi Trainee

Offline

I didn't think Steve was making the lower quarter/dogleg patch in this repair. I though that was a repair to the outer portion of the inner sill.You are NOT doing this right.The repair panel must be shaped a bit at the bottom.Also there is a cage nut

that must be installed prior to welding the panel on. There is some access to the inside, so any warping

can be dealt with later. Never weld close to a bonded joint. DO NOT become your avatar in real life.

Mad dog

Now that I look at it again, I might be wrong.

Offline

Looking at the work now, I think that a number of plug welds (like spot welds, only done thru a small hole in one flange) would be the ticket. You almost certainly will not burn these thru and you can back up the lower panel with copper sheet to guarantee it.

Bob

Bob