mrv8q

Luke Skywalker

Offline

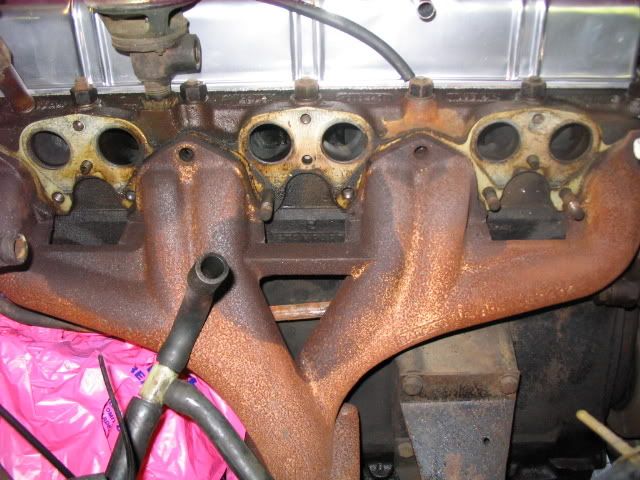

Hello, BCFers, this is concerning my '74 TR6; I'm in the midst of refreshing all the water hoses, intake and exhaust gaskets, etc. I've got a couple questions about studs:

This shows the block, minus the intake manifold and carbs. Volume 1 of the Spare parts catalog, plate AK, shows (4) 105124 studs (shorter), and (6) 105125 studs, (longer). Can anyone say specifically where the shorter studs go? This car was a mish-mash of bolts instead of studs; also, I've never worked on a car where more studs came out instead of the nuts. Also in the pic, there are 3 holes up top where the intake manifold attaches. Plate BY shows these three studs as 111456. Does anyone know what kind of stud this is? (uses a 1/2" nut to secure, instead of a 9/16ths). I'd rather run down to my FLAPS to get them, instead of waiting for TRF; the old ones were nearly destroyed getting them out...

Replacing the studs, should I use a Thread-locker, like Loctite red, on the cylinder block side?

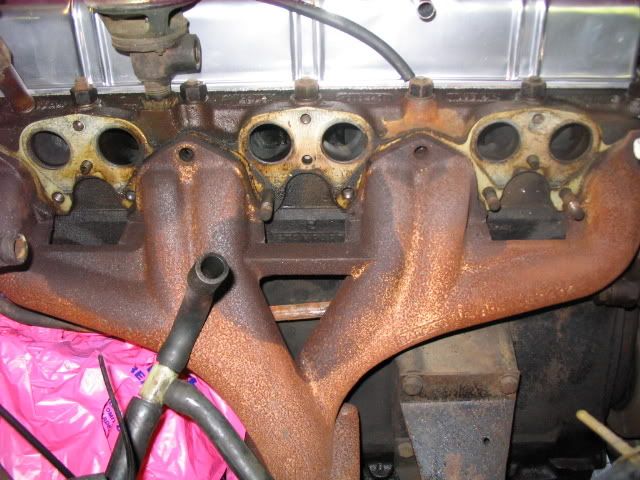

Lastly, sadly, here is the water pipe thru the intake manifold:

Can these pipes be replaced; any recommendations? Thanks, all!

This shows the block, minus the intake manifold and carbs. Volume 1 of the Spare parts catalog, plate AK, shows (4) 105124 studs (shorter), and (6) 105125 studs, (longer). Can anyone say specifically where the shorter studs go? This car was a mish-mash of bolts instead of studs; also, I've never worked on a car where more studs came out instead of the nuts. Also in the pic, there are 3 holes up top where the intake manifold attaches. Plate BY shows these three studs as 111456. Does anyone know what kind of stud this is? (uses a 1/2" nut to secure, instead of a 9/16ths). I'd rather run down to my FLAPS to get them, instead of waiting for TRF; the old ones were nearly destroyed getting them out...

Replacing the studs, should I use a Thread-locker, like Loctite red, on the cylinder block side?

Lastly, sadly, here is the water pipe thru the intake manifold:

Can these pipes be replaced; any recommendations? Thanks, all!

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

.jpg)

.jpg)

.jpg)