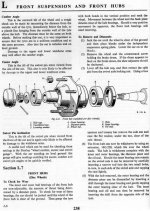

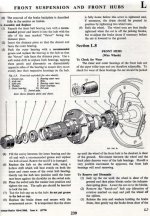

I am in the process of replacing the front wheel bearings on a 1959 AH 3000.

I am retaining the distance piece and appropriate shims.

I have been told that there is an acceptable end float for the front wheel bearings, but I cannot find it in the BMC shop manual.

Does anyone where this information is documented, or what the allowable end float should be?

Thanks.

Ron

I am retaining the distance piece and appropriate shims.

I have been told that there is an acceptable end float for the front wheel bearings, but I cannot find it in the BMC shop manual.

Does anyone where this information is documented, or what the allowable end float should be?

Thanks.

Ron

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>