-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Front tilt bonnet latch

- Thread starter Rut

- Start date

Jim_Gruber

Yoda

Offline

Rut one of the neatest one I ever saw used a pair of locator pegs mounted on back if bonnet that made contact with a Soring loaded receiver mounted on the hinge brackets. A singke cable release operated both spring mounted latch releases. Other idea is the speedwell setup, pricey but interesting.

Hot Wings

Senior Member

Offline

>> would like your thoughts.

Thanks, Rut

I like the idea because I don't want any exterior fasteners. Those "T" handle rubber straps are fin on trucks and Baja Bugs, but not on Bugeyes.

What I've been contemplating is something like the old BMW hoods that lifted up and forward a few inches and then pivoted forward to the up position. IIRC some Saabs also had similar mechanisms. "Landing pads" could then be fabricated using the stock hinge points that slide together on closing securing the aft portion of the hood. A single forward latch would then be all that is needed to keep the hood in place.

Jim_Gruber

Yoda

Offline

One of the hot rod type specialty sites wil gave sone sort of hood release latch. I'd look there I wish I still had the picture of this setup but it went missing a long time ago. Was on an iris blue BE.

Rut

Obi Wan

Offline

Jim,

that sounds like a really neat set up and it sounds like it would be hidden. Hot Wings, I'm not sure what you're saying, but the less complicated for me the better. On the front tilt set up it doesn't take much to secure the bonnet at the rear and I've even toyed with magnets. The T handled rubber may be more than I need, but since it's hidden it might be a viable solution. I also want to use a track system on the sides to keep the alignment or maybe just a locating pin. More input?

Thanks, Rut

that sounds like a really neat set up and it sounds like it would be hidden. Hot Wings, I'm not sure what you're saying, but the less complicated for me the better. On the front tilt set up it doesn't take much to secure the bonnet at the rear and I've even toyed with magnets. The T handled rubber may be more than I need, but since it's hidden it might be a viable solution. I also want to use a track system on the sides to keep the alignment or maybe just a locating pin. More input?

Thanks, Rut

Jim_Gruber

Yoda

Offline

Rut I just used SS Draw Latches that were adjustable from McMaster Carr catalog for Bugsy I. Relatively inexpensive. You need something adjustable and strong. I broke 2 sets of Winner Circle latches before I found these. No other guides are needed. Bonnet will sort of self align in the rear on opening and closing. Need to raise from PS as there is a need to give a slight push to clear the wiper motor when going up. mount with 3 screws on latch and two for the hook.

Hot Wings

Senior Member

Offline

Jim,

that sounds like a really neat set up and it sounds like it would be hidden. Hot Wings, I'm not sure what you're saying,

Basicilly like this:

https://www.youtube.com/watch?v=X28zi8xw7Hw

I'm kind of wanting a front bumper so I'll need some way of clearing that with a forward tilting hood. Guide rails of an old BMW 5 series might be transplantable on the rear. The forward stock latch could be used as is.

Jim_Gruber

Yoda

Offline

That's the Speedwell solution. IMHO Hard to initially set up and align. I have found with ForwRd tilt the bonnet will change shape over time and some adjustment is required to keep bonnet right.

Jim_Gruber

Yoda

Offline

You could use the bumpers with front tilt I believe but rear bolt on bumper bracket would need to be attached to bonnet not frame iron. May run into clearance issue as bonnet pivots up. May not be enough room. The bonnet on Bugsy I would go up and front edge on bonnet had about 2" of clearance.

Hot Wings

Senior Member

Offline

That's the Speedwell solution.

Been away from the Sprite world for quite a while and have not seen this option. Are there any pictures on the net to take a look at? Both of my Sprites came with forward tilt hoods. In both cases the rear hinges were simply unbolted and rubber straps added to the sides. The tilt hinge was the original hood latch pegs. Crude, but simple. Made complete removal a 60 second job with 2 people.

Last edited:

Gerard

Luke Skywalker

Offline

You could use the bumpers with front tilt I believe but rear bolt on bumper bracket would need to be attached to bonnet not frame iron. May run into clearance issue as bonnet pivots up. May not be enough room. The bonnet on Bugsy I would go up and front edge on bonnet had about 2" of clearance.

My hinge kit can be used with or without the bumper. You are correct about only one bumper bolt being attached to the hinge components.

https://gerardsgarage.com/Garage/Tech/tilthinge/tilthingeWS.htm

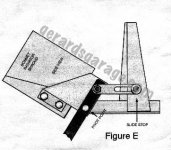

I need to get these pix on my web page, but here's one good, though not real simple solution for a latch.

Hot Wings

Senior Member

Offline

but here's one good, though not real simple solution for a latch.

And with one huge potential problem. These look like standard VW bug components, and when the cable breaks you need a second way to get the hood open. On the VW you can cut the hood handle into sections and unscrew the unit from the outside. There seems to be no such second chance with this setup?

Jim_Gruber

Yoda

Offline

Gerard those are the pics I was thinking about. I agree on the risk of a cable breaking. Here is what I used. Adjustable and with a Safety Catch. Go for Stainless. Go to McMaster Carr and Google Adjustable Draw Latches.

[h=3]Adjustable Draw Latches[/h]

A threaded rod lets you adjust the latch distance to compensate for gasketing and misalignment.Choose latches with an enclosed or exposed threaded rod (on enclosed latches, the threaded rod is covered by the handle when the latch is closed). Mounting screws not included.Nonlocking Latches with Safety Catch—Have a secondary release to prevent accidental opening.Note: Overall length includes strike; measured with rod extended to maximum latch distance.

For technical drawings and 3-D models, click on a part number.

For technical drawings and 3-D models, click on a part number.

[h=3]Adjustable Draw Latches[/h]

D

A threaded rod lets you adjust the latch distance to compensate for gasketing and misalignment.Choose latches with an enclosed or exposed threaded rod (on enclosed latches, the threaded rod is covered by the handle when the latch is closed). Mounting screws not included.Nonlocking Latches with Safety Catch—Have a secondary release to prevent accidental opening.Note: Overall length includes strike; measured with rod extended to maximum latch distance.

Overall Size | ||||||||

|---|---|---|---|---|---|---|---|---|

| Material | Latch Distance | Lg. | Wd. | Proj. | Screw Size | Each | ||

| Enclosed Latches—Handle covers the threaded rod when latch is closed. | ||||||||

| Nonlocking with Safety Catch | ||||||||

| D | Zinc-Plated Steel | 1 3/4"-2 3/8" | 3 1/8" | 1 1/8" | 13/16" | #6 | 1864A23 | $8.61 |

| D | Yellow Zinc-Plated Steel | 2"-2 1/2" | 3 1/16" | 1 1/8" | 13/16" | #6 | 1864A15 | 7.73 |

| D | 300 Series Stainless Steel | 2"-2 1/2" | 3 1/16" | 1 1/8" | 13/16" | #6 | 1864A17 | 15.42 |

Gerard

Luke Skywalker

Offline

And with one huge potential problem. These look like standard VW bug components, and when the cable breaks you need a second way to get the hood open. On the VW you can cut the hood handle into sections and unscrew the unit from the outside. There seems to be no such second chance with this setup?

Not my solution, just one I saw at the Palo Alto all British Meet maybe 10 years ago, so I can't comment on any backup options. Given the amount of use, I think there's little risk of breakage, but yes, I suppose there is that potential problem with the pictured design. I worked out something (still incomplete) but similar, about 15 years ago. I'm not at the stage of getting back to work on that, so it remains incomplete, but it is much less complicated.

I think Tom Colby's design solution is rather simple and elegant.

apbos

Jedi Knight

Offline

Rut

Combined with this hinge mechanism https://www.britishv8.org/Other/BruceUchida.htm would really be cool. Alot of engineering though.

Combined with this hinge mechanism https://www.britishv8.org/Other/BruceUchida.htm would really be cool. Alot of engineering though.

Gerard...How about you offer these latches to go with your hinges? I will be one of your first customers! I want a hidden type latch (where I don't have to make significant new holes) and was seriously in the thought process on how to use the existing hinge mount points on the bonnet and the ones in the firewall. This fits in right along what I want.

...Bill

...Bill

Gerard

Luke Skywalker

Offline

Gerard...How about you offer these latches to go with your hinges? I will be one of your first customers! I want a hidden type latch (where I don't have to make significant new holes) and was seriously in the thought process on how to use the existing hinge mount points on the bonnet and the ones in the firewall. This fits in right along what I want.

...Bill

hahaha... Thanks Bill, but I'm already losing enough money on the specialized parts I make that many here would rather make/copy themselves or buy something inferior for a little less. Anybody who's done any manufacturing will understand what I mean. Unless you build mass quantities in China, there's no money to be made with quality American made stuff.

Hot Wings

Senior Member

Offline

hahaha... Thanks Bill, but I'm already losing enough money on the specialized parts I make that many here would rather make/copy themselves or buy something inferior for a little less. Anybody who's done any manufacturing will understand what I mean.

Been there, done that, and have been thinking about trying it again (some fools just never seem to learn :friendly_wink