Hi Peter,

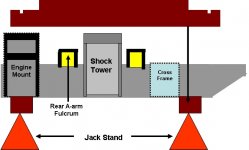

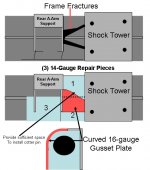

I have attached the original 1999 document describing the reinforcements. Since I applied the suspension pivot gusset with the engine installed, I also designed frame supports to maintain its alignment when being jacked up. Keep in mind that I applied the gusset as part of a frame tare repair caused by a bout of aggressive driving.

Robin Astle, BN7 (now 70% complete!)

Leicester, UK.

r.astle@pipemedia.co.ukTo my knowledge, there were three areas which came in for reinforcement on the works rally cars. These were the engine mounts, the front suspension lower wishbone brackets and the tops of the chassis rails where they pass below the rear axle. It must be remembered that these cars had 200BHP+ engines and came in for rougher treatment that the average road car.

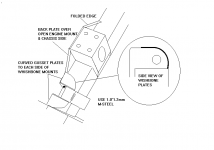

Editor's note: Even if you don't plan to modify your chassis, check out these areas. I've seen quite a few street cars with chassis rail cracks at the engine mounts and flatten chassis rails under the rear axle. Our cars are at least 30 years old and they weren't always treated right.The engine mount mod' was to prevent distortion of the open backed mounting and cracking of the chassis rails. A new back plate is used to cover the open back of the mounting and extends to the bottom of the chassis rail. It forms a gusset each side of the mount at about 45 deg. making the total length at the chassis about 3 times the width of the top of the engine mount thereby spreading the loads into the chassis. The edge of the gussets are folded over by about 6mm (0.25") to increase stiffness.

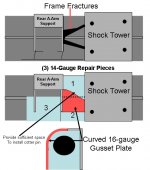

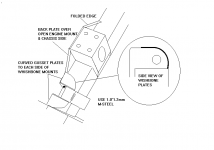

The wishbone brackets are all fitted with gusset plates to prevent distortion. The plates are about 38mm (1.5") wide, starting at the outer-upper chassis rail and following the bracket edge round, terminating to leave just enough space to get the suspension pin in place and tighten up the nuts. The inner plates extend to the spring turrets.

Worn shock absorbers / dampers or regular low flying can lead to excessive movement of the axle, this puts a dent in the top of the chassis rail which then bends. My car was in this state when I got it. The repair involved temporarily welding the head of a bolt to the chassis at the dent, and with a nut, tightening down on to a spreader beam resting on wooden shims about a foot each side of the dent. Three attempts with the bolt in different places pulled the dent out and straightened the chassis. The reinforcement is to tack weld two profiled plates complete with holes for the rebound rubber, to each side and top of the chassis rail.

In all cases use mild steel about 1.6mm (1/16") thick.

Ray(64BJ8P1)

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>