-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

First time putting front hubs on - any tips

- Thread starter tdskip

- Start date

TR3driver

Great Pumpkin - R.I.P

Offline

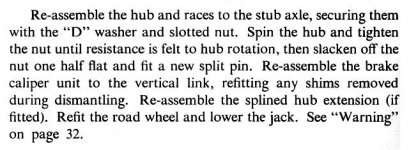

I think we discussed this before ... if you are installing new felt seals, you should do a trial fitting without the seal to set the bearing clearance. Then mark the nut location, remove the hub, install the seal and put the nut back where it was. Otherwise, the felt may interfere with setting the bearing clearance.

I also rather like Geo's tip of JB Welding a 10-32 nut inside the dust cap, to which I then add a short 10-32 screw to block the hole in the cap. The nut makes it much easier to remove the cap in the future (remove the short screw and insert a longer one, which will force the cap off).

Also worth noting perhaps that the new rotors I got from a supplier in the UK (on sale at a show) were significantly off balance. I removed enough metal from one so the assembled hub wouldn't turn under it's own imbalance, but didn't take the other far enough it seems, and there is noticeable vibration at higher speeds. So I'm going to have to revisit the subject soon.

I also rather like Geo's tip of JB Welding a 10-32 nut inside the dust cap, to which I then add a short 10-32 screw to block the hole in the cap. The nut makes it much easier to remove the cap in the future (remove the short screw and insert a longer one, which will force the cap off).

Also worth noting perhaps that the new rotors I got from a supplier in the UK (on sale at a show) were significantly off balance. I removed enough metal from one so the assembled hub wouldn't turn under it's own imbalance, but didn't take the other far enough it seems, and there is noticeable vibration at higher speeds. So I'm going to have to revisit the subject soon.

TR3driver said:I think we discussed this before ... if you are installing new felt seals, you should do a trial fitting without the seal to set the bearing clearance. Then mark the nut location, remove the hub, install the seal and put the nut back where it was. Otherwise, the felt may interfere with setting the bearing clearance.

I also rather like Geo's tip of JB Welding a 10-32 nut inside the dust cap, to which I then add a short 10-32 screw to block the hole in the cap. The nut makes it much easier to remove the cap in the future (remove the short screw and insert a longer one, which will force the cap off).

Also worth noting perhaps that the new rotors I got from a supplier in the UK (on sale at a show) were significantly off balance. I removed enough metal from one so the assembled hub wouldn't turn under it's own imbalance, but didn't take the other far enough it seems, and there is noticeable vibration at higher speeds. So I'm going to have to revisit the subject soon.

Hi Randall, yes, a bit of an echo. Sorry.

TR4nut

Yoda

Offline

I just did this on the 3A project, and other than making sure I greased up the bearings thoroughly it went pretty smoothly - with the thinner grease seals I don't think you'll have a problem at all.

The only finicky thing I had was one side where the inner bearing didn't want to go on the axle stub. I cleaned up the stub with a little emory cloth and it went together.

The only finicky thing I had was one side where the inner bearing didn't want to go on the axle stub. I cleaned up the stub with a little emory cloth and it went together.