Offline

Completely Hypothetical!!!

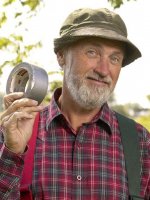

was puttering around the house today and got to thinking about the garage. If you look at the attached picture you will see that I have a post right in the middle of the garage.

The garage itself is about 16 X 16 and there is an apartment over it.

There is not a ton of ceiling height as it, but, engineers, how would I calculate how big a beam I would need should I want to get rid of the post? Either wood or an I beam. Obviously in real life I would get an engineer in and do it properly, I don't want to mess with that, but, ballpark.

any ideas?

I was also thinking that I could presumably put a hoist on an I beam - would that work?

was puttering around the house today and got to thinking about the garage. If you look at the attached picture you will see that I have a post right in the middle of the garage.

The garage itself is about 16 X 16 and there is an apartment over it.

There is not a ton of ceiling height as it, but, engineers, how would I calculate how big a beam I would need should I want to get rid of the post? Either wood or an I beam. Obviously in real life I would get an engineer in and do it properly, I don't want to mess with that, but, ballpark.

any ideas?

I was also thinking that I could presumably put a hoist on an I beam - would that work?

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>