Offline

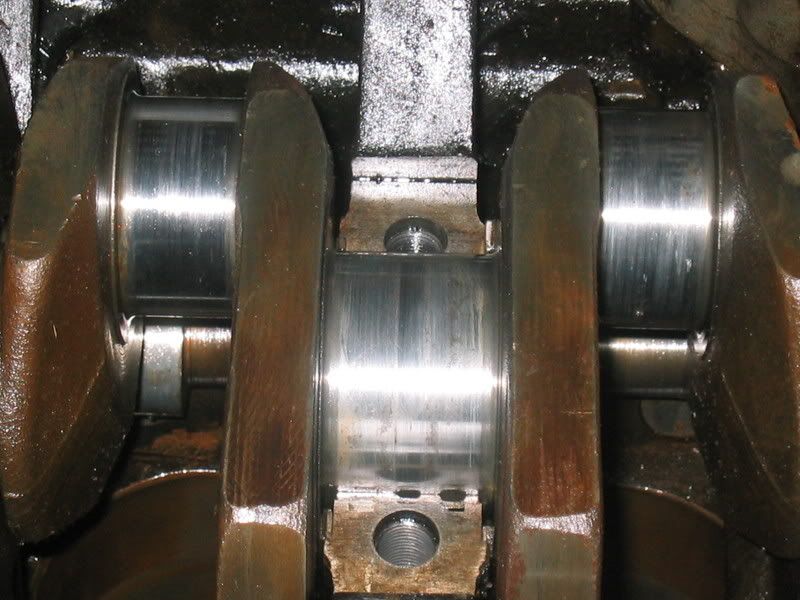

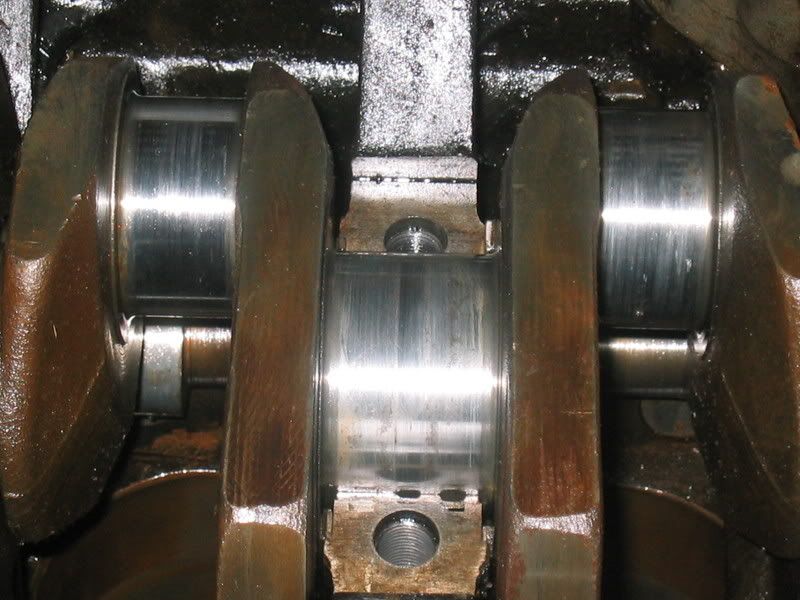

I've got to be honest, before yesterday other than assisting friends in high school. I have never taken apart or rebuilt an engine. I've got to say it was really cool to dismantle this and I got to use my new engine stand and do it with my son to boot who really does not dig cars yet. My question is this. How does this look inside? The engine freely turned and to me does not look that bad inside. As I was snapping some pics I thought it would a neat thing to have start threads and document each of these processes and have the pros of the forum help out the novices. Could be a cool learning experience and confidence booster for some. Any way here are pics of the crank and the pistons. Other than being dirty how do they look? The bearing are still nice & thick and everything looked well lubed.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>