JimTR4

Senior Member

Offline

Hi all,

Need some guidance here. 1964 TR4.

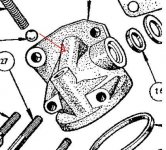

My mechanical oil gauge leaks ever so slightly and I have never been able to remedy it. I am fitting a new dash and don't want to chance getting oil all over it. I have got an electric gauge.

Question - where is the best location to install the pressure sensor/sender? Can it simply be placed where the mechanical gauge's capillary goes?

Many thanks

Jim

Need some guidance here. 1964 TR4.

My mechanical oil gauge leaks ever so slightly and I have never been able to remedy it. I am fitting a new dash and don't want to chance getting oil all over it. I have got an electric gauge.

Question - where is the best location to install the pressure sensor/sender? Can it simply be placed where the mechanical gauge's capillary goes?

Many thanks

Jim

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>