-

Hi Guest!

Hi Guest!

You can help ensure that British Car Forum (BCF) continues to provide a great place to engage in the British car hobby! If you find BCF a beneficial community, please consider supporting our efforts with a subscription.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TR6 Easy way to install rear gaiter on TR6?

- Thread starter SCguy

- Start date

Hello SCguy,

as DNk so succinctly put it, "Take it apart ???", they slide on very easily. Just be sure that the splines are well lubricated with Moly grease before you reassemble them. They are originally secured with steel wire but you can use a cable tie if you like. (You will see a groove around the two halves of the axle shafts where this fastening locates.)

Alec

as DNk so succinctly put it, "Take it apart ???", they slide on very easily. Just be sure that the splines are well lubricated with Moly grease before you reassemble them. They are originally secured with steel wire but you can use a cable tie if you like. (You will see a groove around the two halves of the axle shafts where this fastening locates.)

Alec

T

Tinster

Guest

Guest

Offline

Larry,

This MIGHT work for you. It somehow worked for me.

Put your car on jack stands, remove both rear wheels.

Put a sissor jack under the trailing arm just below the

shock link attachment. Push the T/A upward a little

with the sissor jack, 1/2". Remove the shock link assembly.

Now lower the sissor jack slowly and the coil spring

will push the T/A downward. The axle will move downward

and the U-joint will permit the middle to rotate upward

as well. The axle will bump the frame on it's way downward

and then seperate enough for you to slide the gaiter in place.

If that doesn't work, take a time out cruise. I hope this

helps a bit. If not, the experts will have better methods.

/bcforum/images/%%GRAEMLIN_URL%%/yesnod.gif

This MIGHT work for you. It somehow worked for me.

Put your car on jack stands, remove both rear wheels.

Put a sissor jack under the trailing arm just below the

shock link attachment. Push the T/A upward a little

with the sissor jack, 1/2". Remove the shock link assembly.

Now lower the sissor jack slowly and the coil spring

will push the T/A downward. The axle will move downward

and the U-joint will permit the middle to rotate upward

as well. The axle will bump the frame on it's way downward

and then seperate enough for you to slide the gaiter in place.

If that doesn't work, take a time out cruise. I hope this

helps a bit. If not, the experts will have better methods.

/bcforum/images/%%GRAEMLIN_URL%%/yesnod.gif

bobh

Jedi Warrior

Offline

Larry,

I just went through this exersize while replacing the trailing arm bushings.

The first side was difficult because of self inflicted wounds. The second side was easy.

As mentioned above you can use a jack to raise and lower the trailing arm as needed. Be careful not to try and raise it too much or you will begin to lift tha car off the jackstands.

After you remove the half shaft. Slide the gaiter onto the half shaft that you removed. I used nylon wire ties to secure it.

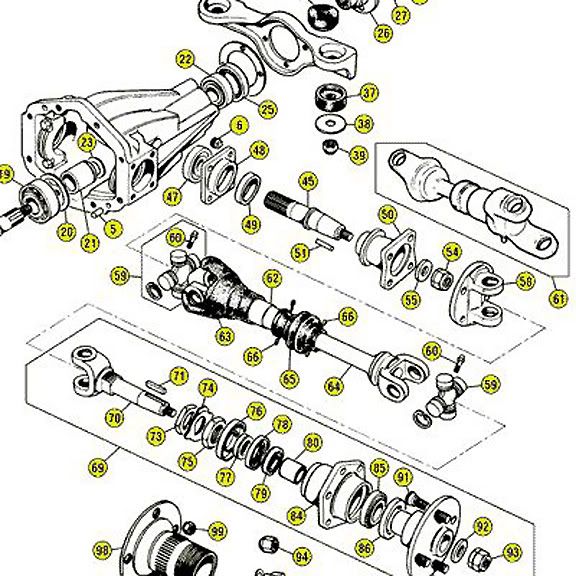

Rotate the shaft still attached to the diff so the key way or slot is at the top. I'm referring to the extra wide slot in the female part of the splines. Apply the lubricant liberally to the inside of the female splines. I used Never Seez Moly.

As you start to install the outer half shaft, rotate it so the male key is at the top. Pull the gaiter back so you can see the splines. You need to line up the key with the key slot and align the centerlines of inner and outer half shafts as close as possible. In otherwords there should be no angle between the centerlines of the inner and outer shafts. The better the alignment and the match of the key the easier and quicker you'll mate the splines. Once they are mated, slide them together, slide the ga

I just went through this exersize while replacing the trailing arm bushings.

The first side was difficult because of self inflicted wounds. The second side was easy.

As mentioned above you can use a jack to raise and lower the trailing arm as needed. Be careful not to try and raise it too much or you will begin to lift tha car off the jackstands.

After you remove the half shaft. Slide the gaiter onto the half shaft that you removed. I used nylon wire ties to secure it.

Rotate the shaft still attached to the diff so the key way or slot is at the top. I'm referring to the extra wide slot in the female part of the splines. Apply the lubricant liberally to the inside of the female splines. I used Never Seez Moly.

As you start to install the outer half shaft, rotate it so the male key is at the top. Pull the gaiter back so you can see the splines. You need to line up the key with the key slot and align the centerlines of inner and outer half shafts as close as possible. In otherwords there should be no angle between the centerlines of the inner and outer shafts. The better the alignment and the match of the key the easier and quicker you'll mate the splines. Once they are mated, slide them together, slide the ga

bobh

Jedi Warrior

Offline

Larry,

I just went through this exersize while replacing the trailing arm bushings.

The first side was difficult because of self inflicted wounds. The second side was easy.

As mentioned above you can use a jack to raise and lower the trailing arm as needed. Be careful not to try and raise it too much or you will begin to lift tha car off the jackstands.

After you remove the half shaft. Slide the gaiter onto the half shaft that you removed. I used nylon wire ties to secure it.

Rotate the shaft still attached to the diff so the key way or slot is at the top. I'm referring to the extra wide slot in the female part of the splines. Apply the lubricant liberally to the inside of the female splines. I used Never Seez Moly.

As you start to install the outer half shaft, rotate it so the male key is at the top. Pull the gaiter back so you can see the splines. You need to line up the key with the key slot and align the centerlines of inner and outer half shafts as close as possible. In otherwords there should be no angle between the centerlines of the inner and outer shafts. The better the alignment and the match of the key the easier and quicker you'll mate the splines. Once they are mated, slide them together, slide the gaiter over the inner shaft and secure with a wire tie.

Applying the grease to the female splines keeps you from having to handle a greasy male spline. Installing the gaiter on the outer shaft first allows you to pull it back and hold it out of the way with the hand that is holding and aligning the splines. If you install it on the inner shaft first you have to fight it to gain clearance to see the splines.

If you don't have a wire tie tool you should consider buying ne. Home Depot has one for about $10. So does Wally World. You want to be sure your tie is tight.

Remember the 6 nuts that hols the hub flange to the trailing arm only require around 15 Ft-Lbs of torque. Check the manual for the exact number.

Hope this helps,

BOBH

I just went through this exersize while replacing the trailing arm bushings.

The first side was difficult because of self inflicted wounds. The second side was easy.

As mentioned above you can use a jack to raise and lower the trailing arm as needed. Be careful not to try and raise it too much or you will begin to lift tha car off the jackstands.

After you remove the half shaft. Slide the gaiter onto the half shaft that you removed. I used nylon wire ties to secure it.

Rotate the shaft still attached to the diff so the key way or slot is at the top. I'm referring to the extra wide slot in the female part of the splines. Apply the lubricant liberally to the inside of the female splines. I used Never Seez Moly.

As you start to install the outer half shaft, rotate it so the male key is at the top. Pull the gaiter back so you can see the splines. You need to line up the key with the key slot and align the centerlines of inner and outer half shafts as close as possible. In otherwords there should be no angle between the centerlines of the inner and outer shafts. The better the alignment and the match of the key the easier and quicker you'll mate the splines. Once they are mated, slide them together, slide the gaiter over the inner shaft and secure with a wire tie.

Applying the grease to the female splines keeps you from having to handle a greasy male spline. Installing the gaiter on the outer shaft first allows you to pull it back and hold it out of the way with the hand that is holding and aligning the splines. If you install it on the inner shaft first you have to fight it to gain clearance to see the splines.

If you don't have a wire tie tool you should consider buying ne. Home Depot has one for about $10. So does Wally World. You want to be sure your tie is tight.

Remember the 6 nuts that hols the hub flange to the trailing arm only require around 15 Ft-Lbs of torque. Check the manual for the exact number.

Hope this helps,

BOBH