mjobrien

Jedi Trainee

Offline

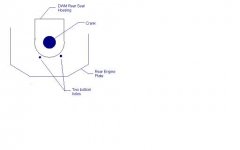

I'm installing the rear seal for the 100 and noticed that the two bottom rear engine plate bolts will not fit as designed. These are the two smaller bolts that go into the rear Main Cap.

Some of the early engines did not have these two bolts so are they optional? Not sure if I need to source cap head socket screws for these locations or use w/out them?

Thanks,

Michael.

Some of the early engines did not have these two bolts so are they optional? Not sure if I need to source cap head socket screws for these locations or use w/out them?

Thanks,

Michael.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

I know next to nothing 'bout 100's. If you do use the silicone, make sure your metal parts are squeaky clean. I've seen fixes that were "less than" using it on the rear cap-to-block area. But the engine was in the car, so the silicone sagged out before it set. Basically, made a gummy worm that pulled out easily. I'm with Bundy with putting bolts in those two lower holes. I don't know if you could find the correct thread, but 12 point bolts have a smaller head too.

I know next to nothing 'bout 100's. If you do use the silicone, make sure your metal parts are squeaky clean. I've seen fixes that were "less than" using it on the rear cap-to-block area. But the engine was in the car, so the silicone sagged out before it set. Basically, made a gummy worm that pulled out easily. I'm with Bundy with putting bolts in those two lower holes. I don't know if you could find the correct thread, but 12 point bolts have a smaller head too.