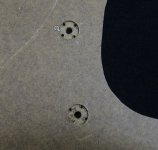

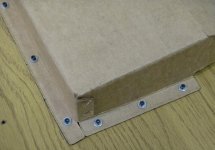

I'm in the process of restoring the interior panels on a 1959 TR-3A. I've built new door panels and since the door pockets are still serviceable I'll be using them. The original rivets that secured the pocket to the panel could not be salvaged so I'm trying to find some type of rivet to replace the old ones. A nice feature of the original ones was a very thin and flat head that did not leave a bulge in the vinyl covering.

Does anyone know of a source for the original rivet or a similar rivet that would serve that same purpose? I have a work around in mind but I'll hold that thought for the moment to see if the rivets are available.

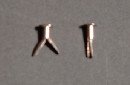

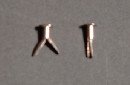

Here's a "fuzzy" photo of the original rivets.

Rick...

Does anyone know of a source for the original rivet or a similar rivet that would serve that same purpose? I have a work around in mind but I'll hold that thought for the moment to see if the rivets are available.

Here's a "fuzzy" photo of the original rivets.

Rick...

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>