I am doing a minor tune up on a 59 TR3a; plugs, points, condenser, etc. I am using the static timing procedure described on the Macy's Garage website. The car ran reasonably well before I started, but now it won't start. I noticed that with the distributer cap off if I try twisting the rotor, there is a considerable amount of wiggle in it. The rotor is not loose on the four sided cam, but the whole cam wiggles with the rotor. Is this normal or should it be tight?

-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TR2/3/3A Does your rotor wiggle

- Thread starter TR Mike

- Start date

I thought that might be the case since the car ran well before I started. I just never noticed the "wiggle" before and wanted to make sure I hadn't loosened something that was now causing my starting problems. I will start back the beginning of the procedure and try it again today.

Thanks for the response.

Thanks for the response.

CJD

Yoda

Offline

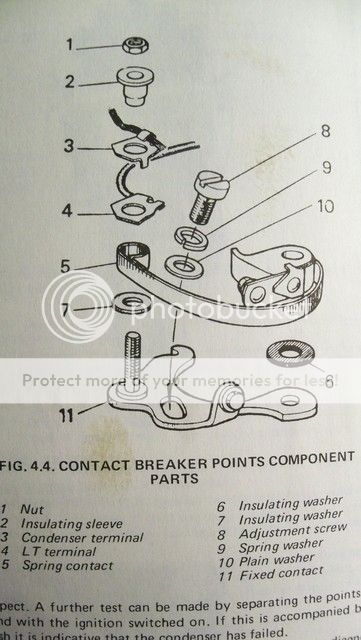

If you put points on, check to make sure the wire from coil and condenser are in the correct order and have the insulator in the correct position. You may be grounding out the points.

That's a good "point". These cars are so old that the hot wire to the points can break or ground as it enters the distributor and makes the tight turn to the point assembly.

Thanks for the responses. I started over from the beginning the next day. I am not sure what my actual problem was but I am up and running now.

The procedure for setting the timing on the Macy's Garage website is very well written. It doesn't address this issue though. The "wiggle in my rotor" was enough to cause the points to be either open or closed depending on the initial position of the rotor. I think you could start with the rotor twisted all the way clockwise, or all the way counterclockwise, and get different results. This may be why it worked on my second try and not my first.

The procedure for setting the timing on the Macy's Garage website is very well written. It doesn't address this issue though. The "wiggle in my rotor" was enough to cause the points to be either open or closed depending on the initial position of the rotor. I think you could start with the rotor twisted all the way clockwise, or all the way counterclockwise, and get different results. This may be why it worked on my second try and not my first.

TexasKnucklehead

Jedi Knight

Offline

It sounds like you have an issue with the mechanical advance. As stated earlier, as much as an additional 15 degrees of advancement is available from the mechanical advance. Two springs on two weights under the points plate should return to 0 when you rotate the rotor. One spring is heavy, and probably not intended to have force on it at rest, but the smaller spring should return the advance to 0 when it is not spinning. The speed of rotation causes the weights to move outward, against the force of the springs (and adds advance). The combined effect of these two springs (and weights) create the "timing advance curve" (actually a knee) but they are intended to start at 0.

Geo Hahn

Yoda

Offline

The weights can get gummed up and not move freely - which may be what you are experiencing. When you twist (wiggle) the rotor to its advanced position it should snap back smartly when released. Sounds like yours just stays where you put it. The will mess up timing at idle &/or speed with poor running as a result.

Removing the rotor and the base plate (two small screws) from the distributor will reveal the workings of the springs and weights. A thorough cleaning of that area may be in order.

Further disasembly is possible by removing the springs, the cam and the weights - though getting it just as far as shown in the photo may be enough for a light cleaning.

Removing the rotor and the base plate (two small screws) from the distributor will reveal the workings of the springs and weights. A thorough cleaning of that area may be in order.

Further disasembly is possible by removing the springs, the cam and the weights - though getting it just as far as shown in the photo may be enough for a light cleaning.

OK, that makes sense. You are right, when I twist my rotor it stays where I put it. It does not snap back to an original position. If it did, then the Macy's Garage procedure would have consistent results. I won't have time for a few days to look at it further, but it sounds like I might see some improvement with a good cleaning of my distributer. The funny thing is I am happy with the way it is running now. I drove it to the grocery store tonight and didn't have any problems with the way it ran.

CJD

Yoda

Offline

When it's running the weights will tend to take up the "wiggle" room. It's only during start or idle that you will get erratic timing readings with a bad spring. The weights will advance timing to take up the slack, while point drag will tend to retard timing. Above idle the force of the weights overpowers the drag of the points, so the timing advances...which is usually good for moderate driving. At idle the drag of the points may equal the force of the weights, so you'll get some bouncing of the timing.

poolboy

Yoda

Offline

Mike, if you take your car off the road for Winter or repairs, consider sending that distributor to Jeff Schlemmer @ https://advanceddistributors.com/wordpress1/

You won't regret it.

You won't regret it.

I keep thinking that if I mess with it too much I may screw it up enough to make it un drivable. It is supposed to be 97 here in Ohio this weekend. I would rather spend time in the TR instead of the F-150.

Maybe it is best to leave things alone until later in the year.

Maybe it is best to leave things alone until later in the year.