OP

Member 10617

Guest

Guest

Offline

Darrell and Randall,

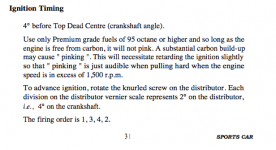

Just to put this one to bed, then, when I use the timing light to measure initial advance, or when I use it to set initial advance, it is giviing me CRANKSHAFT DEGREES. And when I move the vernier knob, I am advancing in DISTRIBUTOR DEGREES. Thus, 2 degrees on the vernier scale is 4 degrees on the crankshaft.

If I am right about this, then I think my problem has been solved (not mechanically but mathematically)!

Just to put this one to bed, then, when I use the timing light to measure initial advance, or when I use it to set initial advance, it is giviing me CRANKSHAFT DEGREES. And when I move the vernier knob, I am advancing in DISTRIBUTOR DEGREES. Thus, 2 degrees on the vernier scale is 4 degrees on the crankshaft.

If I am right about this, then I think my problem has been solved (not mechanically but mathematically)!

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>