2wrench

Luke Skywalker

Offline

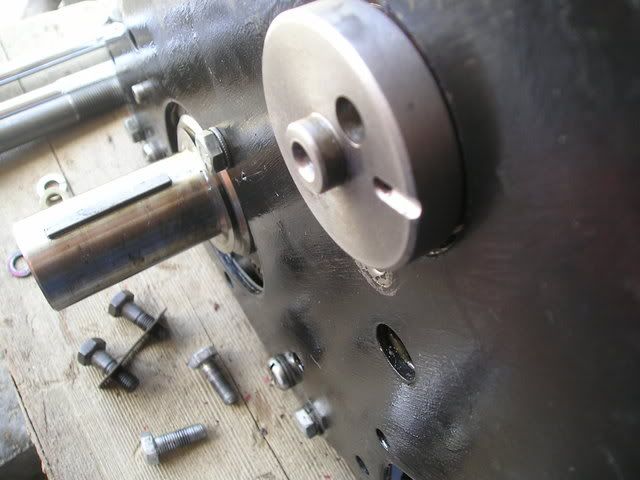

Okay. Kinda like a hair cut. So I gave it a shave;

just a little trim around the edges, huh?

Thanks for the idea, Doc.

Another thought. I have been looking for shim or

shim-type material to place behind the retainer,

between the retainer and the block.

Reason? The groove in the cam flushes so closely

with the face of the block. Was trying to create,

say, .004 tolerance or so there. Makes me think to

try a coat or two (or three?) of paint on the back

side of the retainer.

So if a small amount of paint were to chip off, do

you see a problem? We are talking chain, here, in

speedy rotation. Shouldn't be a problem if it were to

happen, do you think?

just a little trim around the edges, huh?

Thanks for the idea, Doc.

Another thought. I have been looking for shim or

shim-type material to place behind the retainer,

between the retainer and the block.

Reason? The groove in the cam flushes so closely

with the face of the block. Was trying to create,

say, .004 tolerance or so there. Makes me think to

try a coat or two (or three?) of paint on the back

side of the retainer.

So if a small amount of paint were to chip off, do

you see a problem? We are talking chain, here, in

speedy rotation. Shouldn't be a problem if it were to

happen, do you think?

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>