"Suppressor wires are supposed to be about 1KOhm/inch, stranded copper has very little resistance (duh). The length is inconsequential given the speed of the 'signal' (about 300,000km/sec):"

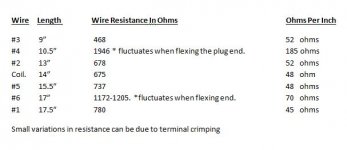

Hi Bob, I think the latest quality performance suppression wire is better than it was a few years ago. And, I also cheated on the test. As with Burt Gummer in Tremors, you were denied critical information. Pat's wire resistance is shown in the attachment below (and, you can easily see two wires are out of spec).

IMO, the best spark plug wire for an old British car with a modern electronic ignition is one that has (i) low EMI transmission and RFI interference to protect the electronic modules in the distributor with (ii) NO MORE resistance per foot than is absolutely necessary for interference protection. Lower resistance spark plug wire usually allows the engine to start more easily and have a smoother idle. You want good EMI/RFI suppression, not higher wire resistance.

I assume most of us are using good quality spiral wound spark plug wire if we have an electronic ignition and are seeking better performance. However, everything in life is a compromise and this is no exception.

Low resistance spiral wire that effectively suppress EMI transmissions and RFI interference is more expensive and OEM automotive manufacturers often use higher resistance fiberglass/carbon core suppression wire instead. Saving several dollars is important to them. I doubt many of us worry about saving a few dollars on spark plug wire.

Today, good quality suppression spark plug wire usually has about 40 to 55 ohms per inch. Small variations in individual wire resistance can be caused by differences in terminal crimping.

Solid Metal Core Wire

We all know solid core wires have no effective EMI/RFI suppression and they should not be used with electronic ignition systems; and they have very low resistance per foot. They are great for older cars with conventional ignitions. Although, solid metal core wire can also work well with Pertronix, 1-2-3 and CSI distributors when used with suppression spark plugs.

Fiberglass/Carbon Core OEM Wire

The latest factory wires tend to be 5000 ohms to 500 ohms per foot (400 to 40 ohms per inch). Most modern cars today are basically computers on wheels and are very sensitive to EMI/RFI transmissions, and manufacturers are conservative as well as cheap. Higher end wire with lower resistance cost them more money. Regardless, the best OEM suppression spark plug wire has about 40 ohms per inch.

Low Resistance Spiral Wire

The most popular plug wire for high performance cars is spiral wound spark plug wire. It has excellent EMI/RFI suppression for electronic ignitions and also has a low wire resistance (less than 40 ohms per inch).

Typical Spiral Wound Spark Plug Wire Resistance:

Heli-Core Wire has 150 - 1,200 ohms per foot (13 to 100 ohms per inch).

MSD 8.5mm Super Conductor has 3 - 4 ohms per inch.

Regards, Bill

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>