T

Tinster

Guest

Guest

Offline

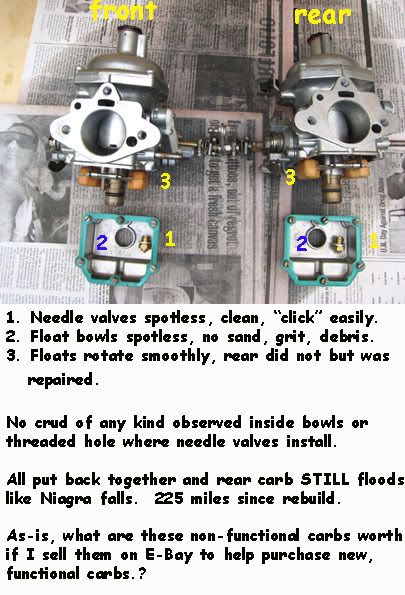

Here's a photo of Crypty's non-functional carbs.

Professionally rebuilt by Jeff Palya approximately

225 miles ago. The rear carb gushes gasoline like

an open faucet.

1. Gas tank removed and cleaned spotless inside.

2. 100% new fuel lines and fittings.

3. Five in-line fuel filters

4.New Moss Motors fuel pump

At everyone's request-3 hours this morning:

Carbs removed from car and observed to be spotless

with no crud, sand, rust, silt or spiders. Rear carb

continues to gush gasoline. Needle valves clear and

clicks easily when rotated 180*. Floats rotate smoothly.

No crud of any kind observed anywhere.

I think it would be a total waste of money to have Jeff

rebuilt the carbs again. What are these carbs worth to

sell on E-Bay in an honest as-is condition? Maybe a carb

expert could fix them. I could use the cash toward

purchasing new carbs.

Professionally rebuilt by Jeff Palya approximately

225 miles ago. The rear carb gushes gasoline like

an open faucet.

1. Gas tank removed and cleaned spotless inside.

2. 100% new fuel lines and fittings.

3. Five in-line fuel filters

4.New Moss Motors fuel pump

At everyone's request-3 hours this morning:

Carbs removed from car and observed to be spotless

with no crud, sand, rust, silt or spiders. Rear carb

continues to gush gasoline. Needle valves clear and

clicks easily when rotated 180*. Floats rotate smoothly.

No crud of any kind observed anywhere.

I think it would be a total waste of money to have Jeff

rebuilt the carbs again. What are these carbs worth to

sell on E-Bay in an honest as-is condition? Maybe a carb

expert could fix them. I could use the cash toward

purchasing new carbs.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>