-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Correct adjustment of front axle of BN6

- Thread starter BN6_2197

- Start date

Offline

it depends on if your running radials or biasply tires. Radials, I'm told should be zero toein, but some people will argue that they run a little toein and the car handles a little better. I run a little toein myself. Toein increases with a person in the car.Gents,

what is the correct adjustment (Toe In ) of the front axle of a BN6. I measured the current settings of my car. It is 1 dgree, 35 sconds toe in. From my understanding of the workshop manual, that is too much toe in. Can anybody help?

Volker

Offline

I believe mine was set at 1/16" degrees toein but it's been a while since it was done. A friend and a string did it with me helping somewhat and it worked good. Maybe a call to Allen Hendrix of Hendrix wire wheel will shed some light on this?Patrick,

I am running Radials. Can you detail on "little toein" in terms of degree. As said, my current setting is 1 degree, 35 seconds. I have no idea if this is still "little" toe in ;-)

Volker

Last edited:

DerekJ

Luke Skywalker

Offline

Volker

The workshop manual does not mention degrees it uses distance. Toe in is 1/16 inch to 1/8th inch. As you live in Germany I suspect that doesn't mean much at all! In metric it is 1.58mm to 3.17mm. You could calculate the angle by geometry. I would always run some toe in even with radials. Some front wheel drive cars have zero toe in and racers will even go to a very slight toe out to assist cornering grip. For road use I would stick to a small amount of toe in.

The workshop manual does not mention degrees it uses distance. Toe in is 1/16 inch to 1/8th inch. As you live in Germany I suspect that doesn't mean much at all! In metric it is 1.58mm to 3.17mm. You could calculate the angle by geometry. I would always run some toe in even with radials. Some front wheel drive cars have zero toe in and racers will even go to a very slight toe out to assist cornering grip. For road use I would stick to a small amount of toe in.

Offline

I corrected my original post. I meant 1/16" of an inch.I believe mine was set at 1/2 degrees toein but it's been a while since it was done. A friend and a string did it with me helping somewhat and it worked good. Maybe a call to Allen Hendrix of Hendrix wire wheel will shed some light on this?

BN6_2197

Jedi Trainee

Offline

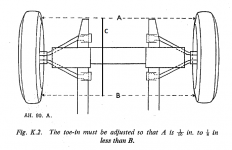

Can anybody detail on the physical reference point at the front wheels for which the difference should be 1/8 to 1/16 inch? Is it the diameter of the complete wheel, the diameter of the rims or the contact area of the whells with the street. The workshop manual is not clear about that.z

Randy Forbes

Yoda

Offline

I use these Longacre Toe Plates to get quick measurements. There is an identical plate against the opposite wheel with the ends of the two (2) tape measures hooked into it.

BN6_2197

Jedi Trainee

Offline

Randy, that means that the B axis mentioned in the workshop manual is located at the inner border of the cmplete wheel and the A axis is located at the outer border of the wheel? In consequence, the distance (back to fromt) between A axis and B axis is the diameter of the complete wheel, isn't it? Hence the 1/8 to 1/16 difference between A and B is relativ to the diameter of the complete wheel and not the diameter of the rims?

If this is true Geometry will help me to calculate the angle I am looking for

Volker

If this is true Geometry will help me to calculate the angle I am looking for

Volker

Offline

You are correct.Randy, that means that the B axis mentioned in the workshop manual is located at the inner border of the cmplete wheel and the A axis is located at the outer border of the wheel? In consequence, the distance (back to fromt) between A axis and B axis is the diameter of the complete wheel, isn't it? Hence the 1/8 to 1/16 difference between A and B is relativ to the diameter of the complete wheel and not the diameter of the rims?

If this is true Geometry will help me to calculate the angle I am looking for

Volker

Randy Forbes

Yoda

Offline

Wouldn't using a tape measure be easier?Randy, that means that the B axis mentioned in the workshop manual is located at the inner border of the cmplete wheel and the A axis is located at the outer border of the wheel? In consequence, the distance (back to fromt) between A axis and B axis is the diameter of the complete wheel, isn't it? Hence the 1/8 to 1/16 difference between A and B is relativ to the diameter of the complete wheel and not the diameter of the rims?

If this is true Geometry will help me to calculate the angle I am looking for

Volker

Offline

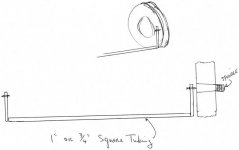

Volker, here is the quick and easy way that works everytime. I've been using this tool ever since my first MGA

way back in 1970. In the beginning I used one made from scrap wood. Some years ago I decided to make one from metal square tubing. Its a little more accurate made with metal. Take the square tubing, cut it to a length that it will fit between the tires. Make the vertical uprights a length that will allow the threaded bolts to point at a point on side wall of the tire at about the height of the spindle or the center of the wheel. for the threaded bolts, drill a hole in the tube at the spindle height large enough to pass the bolt thru. Weld a nut unto the square tubing to give the bolt something to thread thru.

You must measure your front wheels toe setting with the cars weight on the wheels. And the suspension must be at its normal geometry which means that if you have just set it down from a jack, you must roll the car at least 10 feet to get the suspension settled out.

the setting for the Healey is 1/16th inch to 1/8th inch toed-In. As far as I'm concerned I don't care what tires you have. So put the newly built gauge between the front wheels with the screws just touching the side wall of the tires out near the tread. Now move the gauge to the back tread area of the front tires and make the distance 1/16th to 18th inch larger. You don't even have to turn the screws, just let them at the position they were when they touched at the front and you can see the difference. See attached.

way back in 1970. In the beginning I used one made from scrap wood. Some years ago I decided to make one from metal square tubing. Its a little more accurate made with metal. Take the square tubing, cut it to a length that it will fit between the tires. Make the vertical uprights a length that will allow the threaded bolts to point at a point on side wall of the tire at about the height of the spindle or the center of the wheel. for the threaded bolts, drill a hole in the tube at the spindle height large enough to pass the bolt thru. Weld a nut unto the square tubing to give the bolt something to thread thru.

You must measure your front wheels toe setting with the cars weight on the wheels. And the suspension must be at its normal geometry which means that if you have just set it down from a jack, you must roll the car at least 10 feet to get the suspension settled out.

the setting for the Healey is 1/16th inch to 1/8th inch toed-In. As far as I'm concerned I don't care what tires you have. So put the newly built gauge between the front wheels with the screws just touching the side wall of the tires out near the tread. Now move the gauge to the back tread area of the front tires and make the distance 1/16th to 18th inch larger. You don't even have to turn the screws, just let them at the position they were when they touched at the front and you can see the difference. See attached.

Attachments

BN6_2197

Jedi Trainee

Offline

Gents,

to make my under standing christal clear: the length of "C" in the attachment which is a modified version of the workshop manual figure equals to the diameter of the complete wheel and not the rims. Correct?

By the way: I am using this guage to set the correct angle of the toe in https://www.limora.com/en/warehouse...-suspension/suspension-tools/gauge-69990.html

Volker

to make my under standing christal clear: the length of "C" in the attachment which is a modified version of the workshop manual figure equals to the diameter of the complete wheel and not the rims. Correct?

By the way: I am using this guage to set the correct angle of the toe in https://www.limora.com/en/warehouse...-suspension/suspension-tools/gauge-69990.html

Volker

Offline

Yep Volker, I use as much of the complete wheel as possible. As I think you understand, a point on the diameter of the wheel rim and a point on the diameter of the wheel tire tread would/could make your measurement different. But the important thing is to set the pointer at the same relative position on the wheel when measuring from the front of the wheel to the rear of the wheel. I like to set mine to point to the center of the tire side wall, that is surprisingly consistent. (the widest part of the tire).