bigjones

Jedi Warrior

Offline

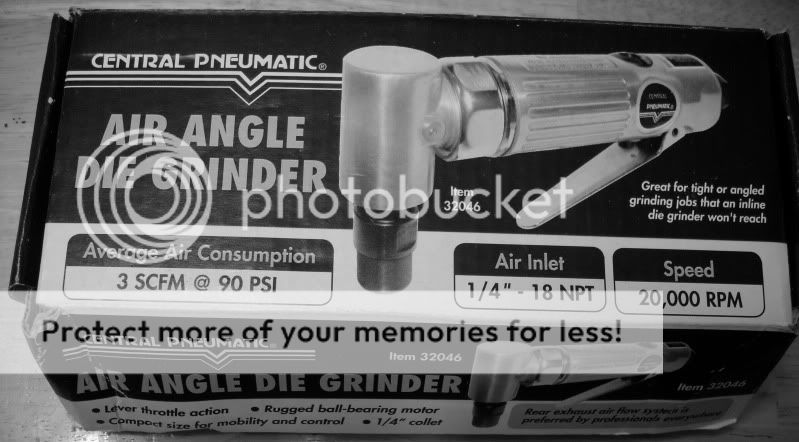

Here's the latest acquisition:

As you can see, it is model #4131, of US components but assembled in Fuji - wow! It's a global economy!

Got it on sale for $12.99 and it was the last one in the store, seriously - does it get any better??!!

Slight problem in that it works for 1.35 seconds and then has to get it's breathe back (like the owner).

This surely has to be a problem with the compressor, right? It's a Bosbitch 1.5 HP, 6 gal, 2.7 cfm @ 90 psi, which is OK for the nail gun, but no one shoots nails bang, bang, bang unless you are Frank or Rambo, right?.

Do I need a bigger compressor?

Cheers!

As you can see, it is model #4131, of US components but assembled in Fuji - wow! It's a global economy!

Got it on sale for $12.99 and it was the last one in the store, seriously - does it get any better??!!

Slight problem in that it works for 1.35 seconds and then has to get it's breathe back (like the owner).

This surely has to be a problem with the compressor, right? It's a Bosbitch 1.5 HP, 6 gal, 2.7 cfm @ 90 psi, which is OK for the nail gun, but no one shoots nails bang, bang, bang unless you are Frank or Rambo, right?.

Do I need a bigger compressor?

Cheers!

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>