When I removed the clutch cylinder on my '60 BN7 for a rebuild, I found an aluminum shim behind the lower mounting bolt. This is a commercially made piece that follows the profile of the flange through which the lower bolt passes. It was trapped behind that flange and fire wall. The 1/16"-thick piece is slotted so that it can be slid between the firewall and the cylinder flange without fully removing the bolt. In addition to that slot, the piece has a half circle cut that reaches midway around the circular portion of the cylinder that goes through the fire wall. I know this piece is commercially made, as one side is raised around the outer perimeter, something that would be extremely difficult to do by hand. I have also recently replaced the brake master cylinder, and no such piece was found on that. Naturally, I forgot to install the piece when I replaced the clutch cylinder, and then lost it into never-never land inside the engine bay when I tried to put it back. While looking for it, I found the bolt that I had dropped into that abyss and replaced earlier. Since someone thought it was important to have the shim in there, I made a new one in similitude of the lost part and installed it. Given the generous potential play between the clutch push rod and the clutch pedal, it wouldn't seem a shim this thin would be a necessity. Postscript! Of course the missing original piece belatedly was found and is on my desk as I write this. I looked in vain for an identification of this part in the factory Service Parts List for the BN7/BT7 cars on Larry Varley's comprehensive Healey Web site. Happy to say I seem to have successfully rebuilt the clutch cylinder and bled the clutch slave, meaning that I now have to restore the transmission cover over my Smitty Toyota gear box and the balance of the car's interior. So, has anyone ever seen such a piece? I now have some scan capability, and could likely figure out how to post a picture.

-

Hey Guest!

Hey Guest!

British Car Forum has been supporting enthusiasts for over 25 years by providing a great place to share our love for British cars. You can support our efforts by upgrading your membership for less than the dues of most car clubs. There are some perks with a member upgrade!**Upgrade Now**

(PS: Upgraded members don't see this banner, nor will you see the Google ads that appear on the site.)

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Clutch Master Cylinder Shim

- Thread starter RDKeysor

- Start date

Randy Forbes

Yoda

Offline

Well, I don't know what they were intended for__did you look for an explanation in the Bentley O/H manual__but it's rare to find them still fitted to the cars, considering the potential number of m/cyl rebuilds in the last 50-60 years.

I do know that they should be fitted in pairs; two (2) shims fitted, to keep the m/cyl mounting flange from being torqued down unevenly.

Not sure if they were ever fitted to the brake m/c too, but I seem to only recall finding them on the clutch side myself.

Speculating, I can only imagine that their purpose was to prevent the stroke from bottoming out the piston inside the cylinder bore.

I do know that they should be fitted in pairs; two (2) shims fitted, to keep the m/cyl mounting flange from being torqued down unevenly.

Not sure if they were ever fitted to the brake m/c too, but I seem to only recall finding them on the clutch side myself.

Speculating, I can only imagine that their purpose was to prevent the stroke from bottoming out the piston inside the cylinder bore.

Offline

...Not sure if they were ever fitted to the brake m/c too, but I seem to only recall finding them on the clutch side myself...

The Moss catalog drawings show them on both clutch and brake pages.

Rob Glasgow

Jedi Knight

Offline

I have a set installed on the clutch MC. I'm not sure it's because of the shims but the clutch pedal is about 1/2" closer to the floor than the brake pedal. I might remove the shim and see if the pedals are the same height.

healeyblue

Jedi Warrior

Offline

Just on the clutch master here as well. Original shims too, none were on the brake master.

Offline

On reflection, maybe they're necessary to make the clutch pushrod return far enough to uncover the return port, given the non-adjustable pushrod and pedal setup.

The reason I suspect this is several years ago when I installed my Smitty 5-speed, I had a situation where the clutch MC wouldn't return all the way, trapping the fluid in the pipe and not allowing it to return upstream when my foot was off the clutch. It had the effect of "riding" the clutch all the time, which started to slip in a few months.

I always blamed the little dust seal next to the circlip (discontinued by Girling) - or sloppy manufacturing tolerances - for causing the piston to be juuuust far enough forward for the return port to be blocked.

But can see without the 1/16" shim between the firewall and the MC, that would move the MC backward relative to the piston, having the same effect as moving the piston forward, riding the clutch.

The reason I suspect this is several years ago when I installed my Smitty 5-speed, I had a situation where the clutch MC wouldn't return all the way, trapping the fluid in the pipe and not allowing it to return upstream when my foot was off the clutch. It had the effect of "riding" the clutch all the time, which started to slip in a few months.

I always blamed the little dust seal next to the circlip (discontinued by Girling) - or sloppy manufacturing tolerances - for causing the piston to be juuuust far enough forward for the return port to be blocked.

But can see without the 1/16" shim between the firewall and the MC, that would move the MC backward relative to the piston, having the same effect as moving the piston forward, riding the clutch.

AUSMHLY

Yoda

Offline

On reflection, maybe they're necessary to make the clutch pushrod return far enough to uncover the return port, given the non-adjustable pushrod and pedal setup.

The reason I suspect this is several years ago when I installed my Smitty 5-speed, I had a situation where the clutch MC wouldn't return all the way, trapping the fluid in the pipe and not allowing it to return upstream when my foot was off the clutch. It had the effect of "riding" the clutch all the time, which started to slip in a few months.

I always blamed the little dust seal next to the circlip (discontinued by Girling) - or sloppy manufacturing tolerances - for causing the piston to be juuuust far enough forward for the return port to be blocked.

But can see without the 1/16" shim between the firewall and the MC, that would move the MC backward relative to the piston, having the same effect as moving the piston forward, riding the clutch.

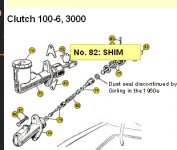

Old post.Are you referring to this?:

View attachment 37385 From the Moss online catalog.

The shims in the diagram (top MC) are for a BN4 to C.E. 48862

OP has a 1960 BN7. Doesn't that car use the bottom MC? No shims shown.

I have a BJ8. My Throw Out Bearing is in constant contact with the release plate. The new TOB had 7mm of graphite. In 500 miles it wore down to 5mm. I'm not ridding the clutch. It's always in contact. Could this problem be related to what you had?

"On reflection, maybe they're necessary to make the clutch pushrod return far enough to uncover the return port, given the non-adjustable pushrod and pedal setup."

"The reason I suspect this is several years ago when I installed my Smitty 5-speed, I had a situation where the clutch MC wouldn't return all the way, trapping the fluid in the pipe and not allowing it to return upstream when my foot was off the clutch. It had the effect of "riding" the clutch all the time, which started to slip in a few months."

My clutch fork isn't binding and moves freely. The clutch slave cylinder push rod is the correct length and moves freely. When installing the slave, I push the rod in to attached to the fork. The pin then returns to about middle. With the clutch fork gaiter removed, I can move the fork by hand to see the TOB move away from the release plate. Let go of the fork, it returns and makes solid contact with the release plate. I'll let the car run for one minute, not using the clutch pedal, transmission is in neutral, I'll see wear on the TOB when I remove it. Photo attached.

What is causing the constant pressure between the TOB and release plate when the clutch pedal in not being used.