CJD

Yoda

Offline

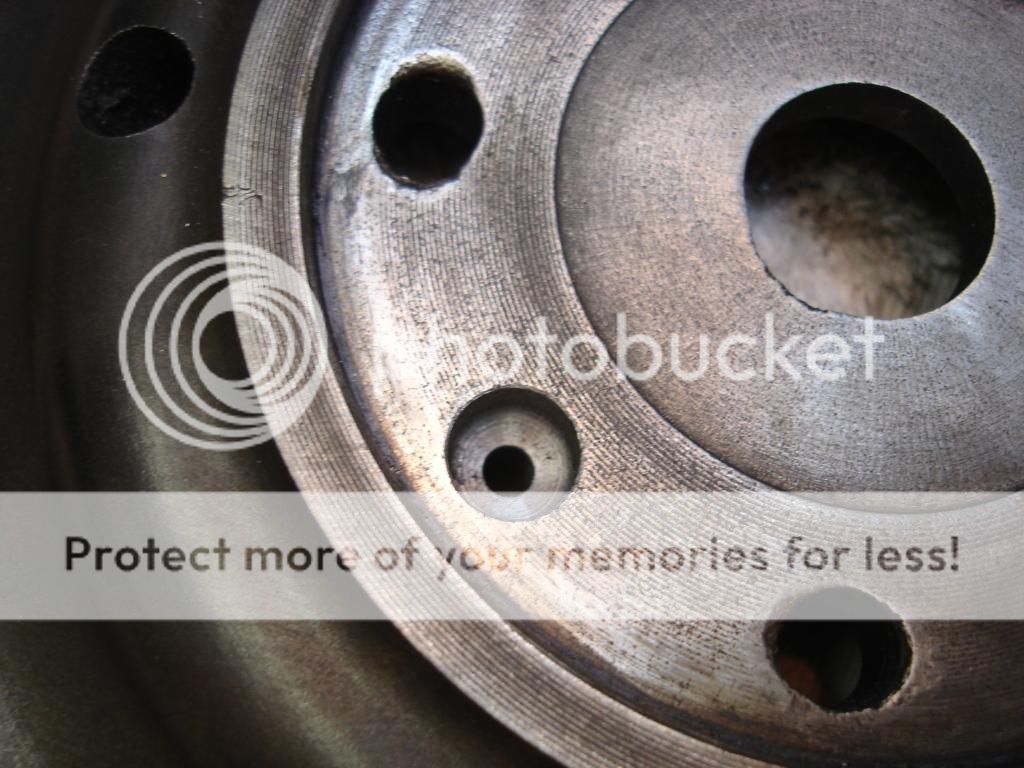

I have run into a bit of a crisis. When I sent the crank and flywheel to the machine shop they were a grungy mess. When they came back...after all the cleaning and machine work was done, I saw a bunch of wallowing around the dowel holes and some scarring. I made a mental note to study it later. Well, later is now.

It appears the flywheel was run loose, and it damaged the threads in the crank. I looked all day for the flywheel bolts without luck...but I now think I had them all along, but they are not right. I have 4 bolts about 7/8" long, marked on the head with "KUMAX 8 8". I'm pretty sure that means metric...although none of my metric taps match them. It appears the PO fixed the wallowed crank threads by re-tapping for these 88 bolts. Bummer. He also left the dowel out completely. Double Bummer.

Of course this has me asking several questions...

1) What were the factory sized flywheel threads?

2) Does anyone have experience with thread inserts on a crank?

3) What size dowel does the crank take?

4) Has anyone studied the clearance between the flywheel bolt heads and clutch disc? I assume the originals had thinner heads for clearance?

Anyway...as usual...I am studying options before I either do something drastic to repair, or just scrap, the crank and flywheel after all that pricey machine work. I'm especially bummed at my machinist for not noticing this before he put the time into these parts...

It appears the flywheel was run loose, and it damaged the threads in the crank. I looked all day for the flywheel bolts without luck...but I now think I had them all along, but they are not right. I have 4 bolts about 7/8" long, marked on the head with "KUMAX 8 8". I'm pretty sure that means metric...although none of my metric taps match them. It appears the PO fixed the wallowed crank threads by re-tapping for these 88 bolts. Bummer. He also left the dowel out completely. Double Bummer.

Of course this has me asking several questions...

1) What were the factory sized flywheel threads?

2) Does anyone have experience with thread inserts on a crank?

3) What size dowel does the crank take?

4) Has anyone studied the clearance between the flywheel bolt heads and clutch disc? I assume the originals had thinner heads for clearance?

Anyway...as usual...I am studying options before I either do something drastic to repair, or just scrap, the crank and flywheel after all that pricey machine work. I'm especially bummed at my machinist for not noticing this before he put the time into these parts...

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>