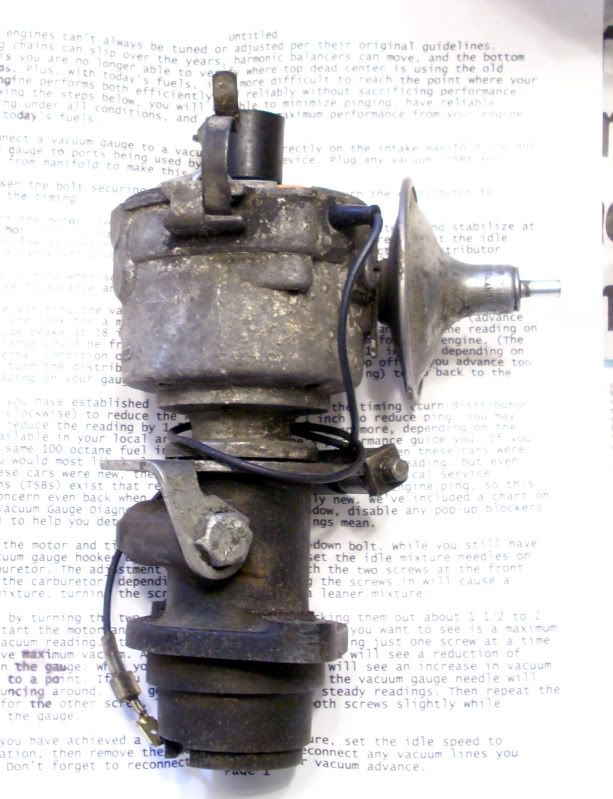

Just to add to Doug's description, this being a UK distributor for a 1500, it has a vacuum advance (rather than the hated vacuum retard) and is fitted with points. Hence it has the spindle with the lobes and so it takes the Pertronix from the 1275 (and happily for me, the TR3). So, I get a dizzy with an advance and it will also serve as a spare for my TR3.

(The Pertronix for the US 1500 is of a slightly different design because it has to fit on a lobeless spindle.)

Also, take a look at this

article (for the MGB engine) that says, on page 17:

"...Remember: if you change either the camshaft profile or timing radically, you'll most likely have to alter the ignition curve.

Probably the worst distributors that you can use are the North American Market specification Lucas 45DE4 or 45DM4 as they use

so much advance and retard to meet US emissions standards that they eliminate any hope of getting real performance from the

engine. The European specification Lucas 45D4, however, is excellent for this purpose...."

Cheers

Hopefully off to Ace Hardware this cold morning for some Nylox brushes (thanks for the tip Doug)

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>