chicken

Jedi Trainee

Offline

Hi guys

Just checking my oil flow over again !! and am finding that not all the rocker arms are feeding oil down the lifter rods, have i got my bushes in wrong ?

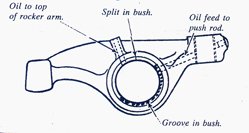

On looking at it again i think the groove in the bush should be uppermost so that the groove aligns with the outlet hole to the rocker screw and that of the hole in the top of the rocker arm (see attached picture of how they are now).

Guess i'll get something right eventually, shoudn't be in to much of a hurry.

Just checking my oil flow over again !! and am finding that not all the rocker arms are feeding oil down the lifter rods, have i got my bushes in wrong ?

On looking at it again i think the groove in the bush should be uppermost so that the groove aligns with the outlet hole to the rocker screw and that of the hole in the top of the rocker arm (see attached picture of how they are now).

Guess i'll get something right eventually, shoudn't be in to much of a hurry.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>