Hi Andy,

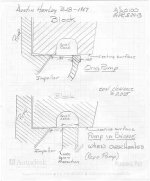

I hadn't thought of cam timing being an issue, and am interested in your method of checking it. I did replace the chain and gears when I had the engine apart, and installed it per the manual, but a quick check would make sure its right.

The delta T across the radiator, at idle and at 190 degrees is now about 9 degrees F. It was about 7F before doing the shroud and new fan. Like you say, its a little tough to measure it at speed but I like your idea of taping the meters to the hood...8^). I don't have any thermocouple meters, but then at speed the car runs now at 175F with 90F ambient, and will go to 180 to 185F if I go up a long hill. I think the car is now at a stage where its cooling system performance is equal to an original build. I need to do better though if I'm to get the A/C working. I would like it to get down to 170F at idle so it can manage the 15 to 20F additional heat load that will be placed on the cooling system.

I'm also going to run a test with an external fan blowing into the radiator to simulate an additional electric fan. It's easy, and cheap to try and see what the results are. I didn't think I could install an electric but in reviewing Bob Boyer's web site, he installed his electric between the grill and X member in front of the radiator. Its only a 12 inch one, but moves 1560 cfm. I don't think it will be enough, but it seems this quest is a alot of small improvements. Another thing the electric fan will do is push air over the top of the radiator at idle. I fear that air is recirculating at idle over the top of the radiator, back into the radiator. Most cars have a seal between the top of the radiator to the hood, preventing this flow. My pickup also has sheet rubber sealing the sides of the radiator to keep air from recirculating, I haven't figured that one out yet, but have been thinking about it....

If you get a chance, post the cam timing check? thanks so much.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>