WHT

Jedi Hopeful

Offline

Hi Bob,

Split lock washers are in my opinion horrible and should not be used. Their design is based on the premise that their split ends dig into the parent material on both sides of the washer to prevent the bolt/nut from turning. So, they damage the parts.

But, even worse, studies by NASA show they can actually cause the bolt to loose tension faster than using just a nut by itself. I would rather use two, hardened and ground flat washers with a reliable locking nut (and usually made-up with a locking gel).

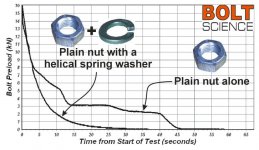

"Helical spring lock washers have been in use for well over 100 years. They are still used on many applications in the belief that they will will "lock" the nut/bolt to the joint and prevent loosening. The body of evidence, based upon both experience and experimental results, is that they do not prevent loosening and can be shown to actually speed up the rate of loosening in many cases. Junker originally showed in his work published in 1969 that these washers are ineffective in preventing loosening. Joints containing these washers have come loose resulting in structural failure leading to both material and human loss."

Regards, Bill

Split lock washers are in my opinion horrible and should not be used. Their design is based on the premise that their split ends dig into the parent material on both sides of the washer to prevent the bolt/nut from turning. So, they damage the parts.

But, even worse, studies by NASA show they can actually cause the bolt to loose tension faster than using just a nut by itself. I would rather use two, hardened and ground flat washers with a reliable locking nut (and usually made-up with a locking gel).

"Helical spring lock washers have been in use for well over 100 years. They are still used on many applications in the belief that they will will "lock" the nut/bolt to the joint and prevent loosening. The body of evidence, based upon both experience and experimental results, is that they do not prevent loosening and can be shown to actually speed up the rate of loosening in many cases. Junker originally showed in his work published in 1969 that these washers are ineffective in preventing loosening. Joints containing these washers have come loose resulting in structural failure leading to both material and human loss."

Regards, Bill

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>