Thanks red57,

I don't know if the bell housing is doweled to the transmission case. I didn't do that and I don't know if any previous caretakers did.

I had the engine rebuilt 200 miles ago. Now that I'm rebuilding the tranny, I noticed the 1st motion shaft end is worn. I checked the condition of the Spigot/Pilot Bush to find it was broken into four pieces. I bought a new one and slid it on the shaft to find there is some play. I inserted it in the engine, with the 1st motion shaft in hand, I slide it in. There is a little play, less then before replacement.

I also have some play with the 1st motion shaft when it's installed in the gear box. There's a new roller cage between the 1st import and the main shaft.

With that knowledge of some play, and I'm using regular bolts, not the 2 dowel bolts, will installing 2 dowel bolts make any difference?

Hi AUSMHLY,

My comments are for a center shift engine and gearbox.

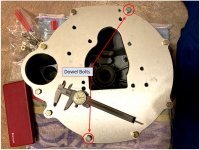

It all depends on how you install the normal bellhousing bolts and the Dowel Bolts (head faces forward or to the rear). This is decided for you in 2 cases since the upper right bolt threads into the block and the lower right Dowel Bolt can only have the head facing to the rear.

The Dowel Bolts have the same shoulder diameter as most Grade 8, 3/8"-24 bolts (0.372-inches). However, the threaded portion of both bolts is only about 0.363-inches in diameter. The real difference then is the shoulder length of the two bolts. Dowel bolts have a shoulder length of 0.757-inches so the shoulder supports both the rear engine back plate and the bellhousing. The other "normal" bolts as sold by Moss have a shorter shoulder length of about 0.312-inches and only support either the back plate or the bellhousing depending on the direction they face.

I personally buy Grade 8 bolts with the correct longer shoulder length to support both and use them in all of the holes when possible; and only install them after installing the two Dowel Bolts and the threaded block bolt. So, I purchase longer bolts and shorten them. I use a shoulder washer and a lock washer to make sure the nuts can be torqued correctly.

If there is a fit problem (a smaller diameter is needed for one of the "normal" bolts to fit into the back plate), I install normal bolts and machine the shoulder diameter to fit.

As you know, the holes for the "normal" bolts are larger in both the bellhousing and back plate, around 0.400-inches in diameter. The holes for the Dowel Bolts are smaller and about 0.372 to 0.375-inches in diameter and have a tight fit. There is no magic here.

And, as you also know, after 50+years, the holes in the bellhousing and back plate can be worn and not always round. I have am installing a Denis Welch back plate to help ensure the best centralization.

You need to measure everything and decide the best way to install the various bolts to centralize the gearbox on the back plate.

Regards, Bill

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>