Riquet1963

Freshman Member

Offline

Hello

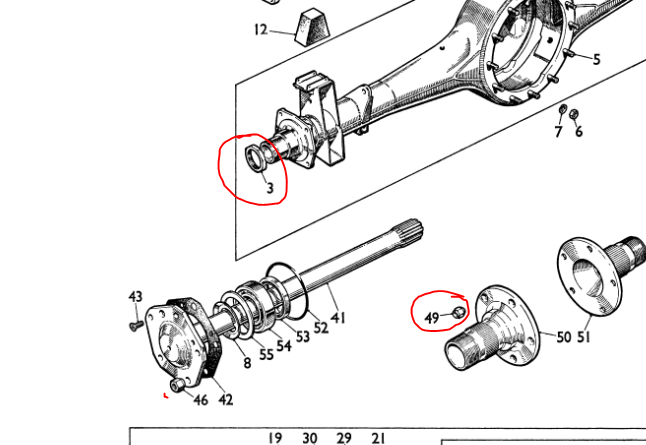

I started to do the maintenance in my rear axle and I have a question about the torque recommended for the two nuts with red circle

If you have more advice for this operation don't hesitate to provide me

Many thanks

Eric G

I started to do the maintenance in my rear axle and I have a question about the torque recommended for the two nuts with red circle

If you have more advice for this operation don't hesitate to provide me

Many thanks

Eric G

Hey Guest!

Hey Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>