OP

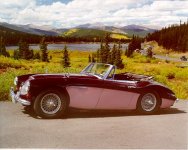

50yrs same Healy

Freshman Member

Offline

In the BJ7 trunk, by the battery support wooden bracket, the inner panel has rusted through. The new panel appears to bolt in? Does it weld too?

Tiny town here - where pickup trucks rule - so I need to tell the shop guy how this goes together. No holes for wood battery support in new part - does this need to be fitted before the inner panel is installed? Has anyone replaced this part that can give me info?

Tiny town here - where pickup trucks rule - so I need to tell the shop guy how this goes together. No holes for wood battery support in new part - does this need to be fitted before the inner panel is installed? Has anyone replaced this part that can give me info?

Hey Guest!

Hey Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>