Guys, I am finally at a point where I can start looking at the interior components of my restoration. I need to do a complete replacement of all of the leather seat covers, panels, and carpet.

My car is a BJ7, and the restoration required all new floor panels, rear seat deck and boot floor.

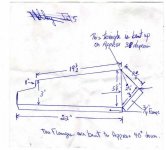

With the interior, my interior rear quarter panels need to be recovered and repaired (pictured below).

I bought a new interior kit from Moss, and it seems like it will work out decently.

One problem I have is the steel frame piece on the rear interior rear quarter panel is heavily rotted on the bottom. Moss's kit included the wood panel, but I need to figure out the sizes and shape of the steel part that the wood attached to.

Has anyone else ran into this issue? Is there a place that I can get a template to fab a new one, or can I buy one.....? I am trying to make a cardboard template, which I could probably get to work out, but I really want it to fit right.

Any suggestions are really appreciated!

Thank you,

Bill

My car is a BJ7, and the restoration required all new floor panels, rear seat deck and boot floor.

With the interior, my interior rear quarter panels need to be recovered and repaired (pictured below).

I bought a new interior kit from Moss, and it seems like it will work out decently.

One problem I have is the steel frame piece on the rear interior rear quarter panel is heavily rotted on the bottom. Moss's kit included the wood panel, but I need to figure out the sizes and shape of the steel part that the wood attached to.

Has anyone else ran into this issue? Is there a place that I can get a template to fab a new one, or can I buy one.....? I am trying to make a cardboard template, which I could probably get to work out, but I really want it to fit right.

Any suggestions are really appreciated!

Thank you,

Bill

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>